Abstract

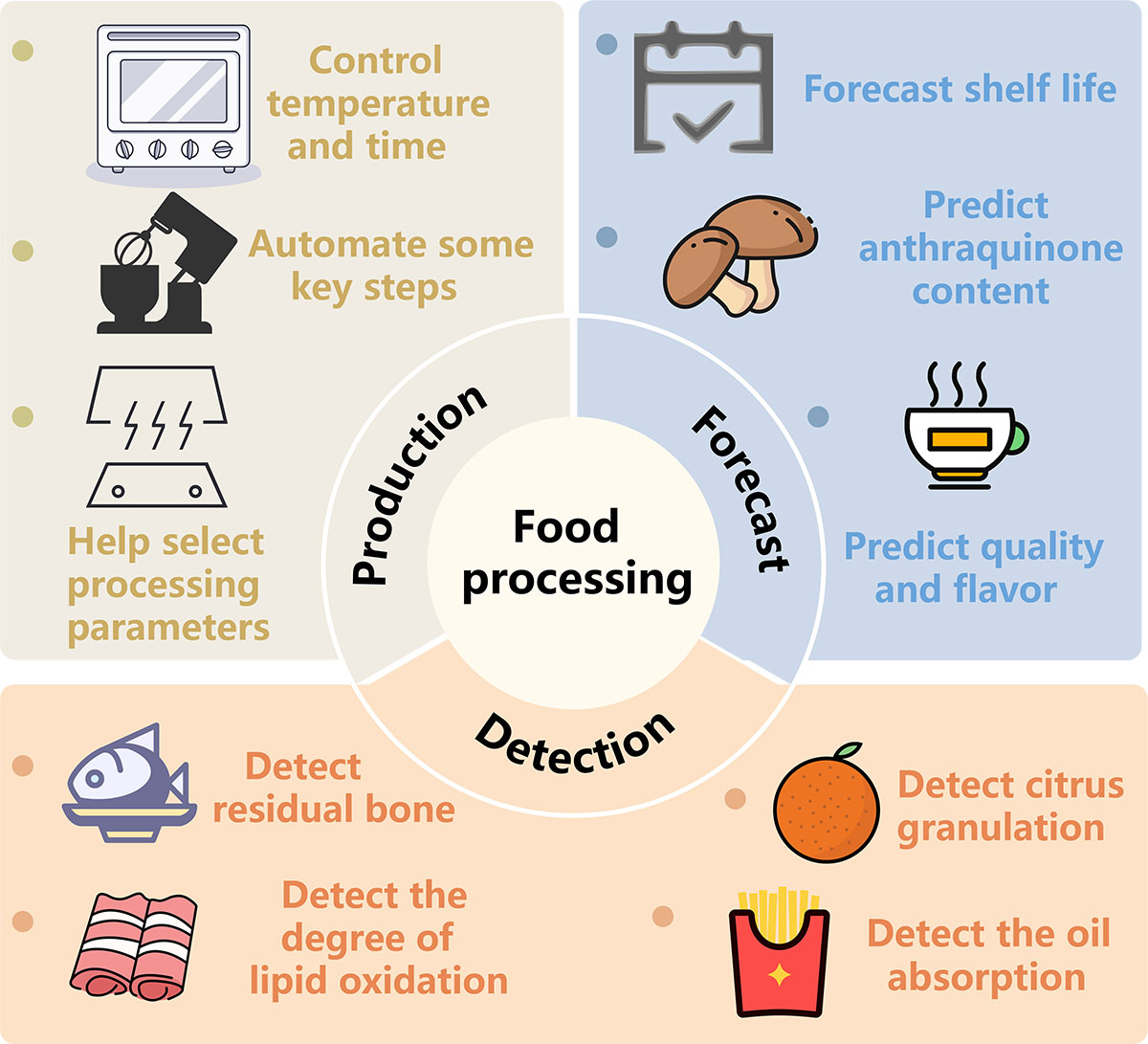

As people’s living standards continue to rise, the food processing industry is facing many challenges such as improving production efficiency, ensuring food safety, and reducing processing costs. The emergence of artificial intelligence (AI) technology has brought new opportunities for this industry. This paper describes AI applications in food processing, especially focuses on machine learning (ML) and deep learning (DL) techniques. These techniques are used for grading and sorting of raw materials, production optimization during food processing, quality inspection, and food safety assurance. For example, ML algorithms can be combined with non-destructive testing techniques. This allows for the effective identification of adulterated meats. The implementation of AI not only improves production efficiency but also enhances food safety and quality control through real-time monitoring and rapid, non-destructive detection methods. Future developments in AI technologies are expected to further promote the sustainable development of the food processing industry by improving data quality, developing more interpretable models, and reducing costs.

Data Availability Statement

Data will be made available on request.

Funding

This work was supported without any funding.

Conflicts of Interest

The author declare no conflicts of interest.

Ethical Approval and Consent to Participate

Not applicable.

Cite This Article

APA Style

Wang, Y. (2025). Application of Artificial Intelligence in Food Industry: A Review. Agricultural Science and Food Processing, 2(2), 68–88. https://doi.org/10.62762/ASFP.2025.552607

Publisher's Note

IECE stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (

https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.