Agricultural Science and Food Processing

ISSN: 3066-1579 (Online) | ISSN: 3066-1560 (Print)

Email: [email protected]

Food processing involves transforming various raw materials, including agricultural products, aquatic products, and livestock, into consumable formats. These formats can be directly consumed, cooked before consumption, or designed to align with human dietary preferences. The processed food industry's growth is closely tied to a nation's economic health and societal well-being [1]. As living standards escalate, consumer expectations regarding food safety and quality standards are likewise intensifying. To cater to this heightened demand for superior food quality, there is a pressing need to devise food analysis techniques that are precise, dependable, and non-destructive [2]. The food processing industry is faced with many challenges such as improving production efficiency, ensuring food safety, and reducing processing costs.

Advancements in technology have led to the emergence of AI technology. As a result, AI has been used in almost every industry, including pharmaceuticals, cosmetics and agriculture [3]. AI is a discipline within computer science, focusing on emulating, augmenting, and broadening human intelligence. It primarily consists of data, algorithms, and computing power. AI can learn from data, make autonomous decisions, and self-optimize, thereby achieving the cognitive, learning, reasoning, and decision-making capabilities inherent in human intelligence [4]. The rise of AI technology has brought new opportunities for the food processing industry. Two primary branches of AI technology, ML and DL, are widely used. Their implementation can improve production efficiency, facilitate the detection of foreign objects to uphold food safety standards, and predict shelf life, which are poised to make substantial contributions to the continued progression of the food processing industry.

ML aims to enable computers to acquire knowledge without explicit programming. It focuses on discovering algorithms capable of learning from and making predictions based on data, shifting away from a reliance on predefined programmatic directives. Therefore, ML algorithms are essentially data-driven [5]. By combining different traditional ML methods with various non-destructive testing techniques, various types of adulterated meats (such as pork, ground beef, and sausages) can be effectively detected [2].

ML includes three main paradigms: supervised learning, unsupervised learning, and reinforcement learning. Within the realm of supervised learning, distinct methodologies are employed for discrete and numerical data, namely classification and regression. In classification tasks, algorithms such as Support Vector Machines (SVM), Discriminant Analysis (DA), Naive Bayes (NB), and K-Nearest Neighbors (K-NN) are widely employed. Conversely, Generalized Linear Model (GLM), Support Vector Regression (SVR), Linear Regression (LR), Gaussian Process Regression (GPR), Ensemble methods, and Decision Tree (DT) can be used for regression [6]. With slight modifications, SVM, K-NN, and DT can serve dual purposes. Among these, SVM is a standout classification algorithm in supervised learning frameworks. Unlike other difference-finding techniques, SVM identifies similarities among samples, making it highly suitable for distinguishing high-quality foods from decaying or perishable ones [7]. For example, SVM can categorize bananas by analyzing their extracted feature vectors, which include attributes like color and texture. This allows for the classification of banana ripeness and the detection of peel defects [7].

Unlike supervised learning, unsupervised learning does not require a training dataset. It includes algorithms like Fuzzy C-Means (FCM), K-Means, Fuzzy Logic (FL) systems, Expert systems, Swarm Intelligence algorithms, and Markov clustering [8, 9]. Expert systems utilize knowledge from various sources to solve complex problems. They are based on the principles and reasoning of human experts. They can imitate the decision-making abilities of human experts, making them powerful tools for decision-making [10].

DL represents a ML technique using ANN. Its benefit is the enhanced ability to independently extract features from raw data. Employing DL improves classification accuracy and reduces error rates [11]. Currently, integrated DL with detection technologies or image processing is widely used as an effective method for assessing fruit quality, tackling problems such as classifying types, predicting nutrient levels, and determining infections or damages.

ANN is the basis for DL, enabling it to make choices or forecasts through the complex interplay of input data. For example, it can accurately predict the makeup and antioxidant traits of banana phenolic compounds [12], like the quality variation in spray-dried black [13], and it can also predict pomegranate oil extraction rates [14]. Multiple ANN types are employed, such as CNN, Recurrent Neural Network (RNN), Deconvolution Neural Network (DNN), Feed-forward Neural Networks (FNN), Modular Neural Network (MNN), Multilayer Perceptron Neural Network (MPNN), and Generative Adversarial Network (GAN) [15]. Among them, RNN is capable of processing sequence data. It has a memory function that captures long-term dependencies in sequences. CNN, a prevalent neural network type, is primarily employed for data processing involving lattice-like topol such as pictures. Pan et al. [16] crafted an advanced method for the multi-category categorization of food images via CNN. The introduction of a novel system named DeepFood was suggested, employing DL to derive detailed and impactful characteristics from a collection of food ingredient imagery, while also enhancing the overall precision of multi-class categorization through sophisticated ML technology. By employing CNN-based DL architecture and cost-effective computer vision modules, it is also possible to quickly detect defective apples on the sorter [17]. In addition, Rauf et al. [18] suggested a DL structure grounded in the CNN methodology for fish species. In terms of identification and classification, the suggested CNN framework comprises 32 profound layers capable of deriving essential distinguishing characteristics from the images. It can be seen that CNN is widely applicable in the realm of food processing.

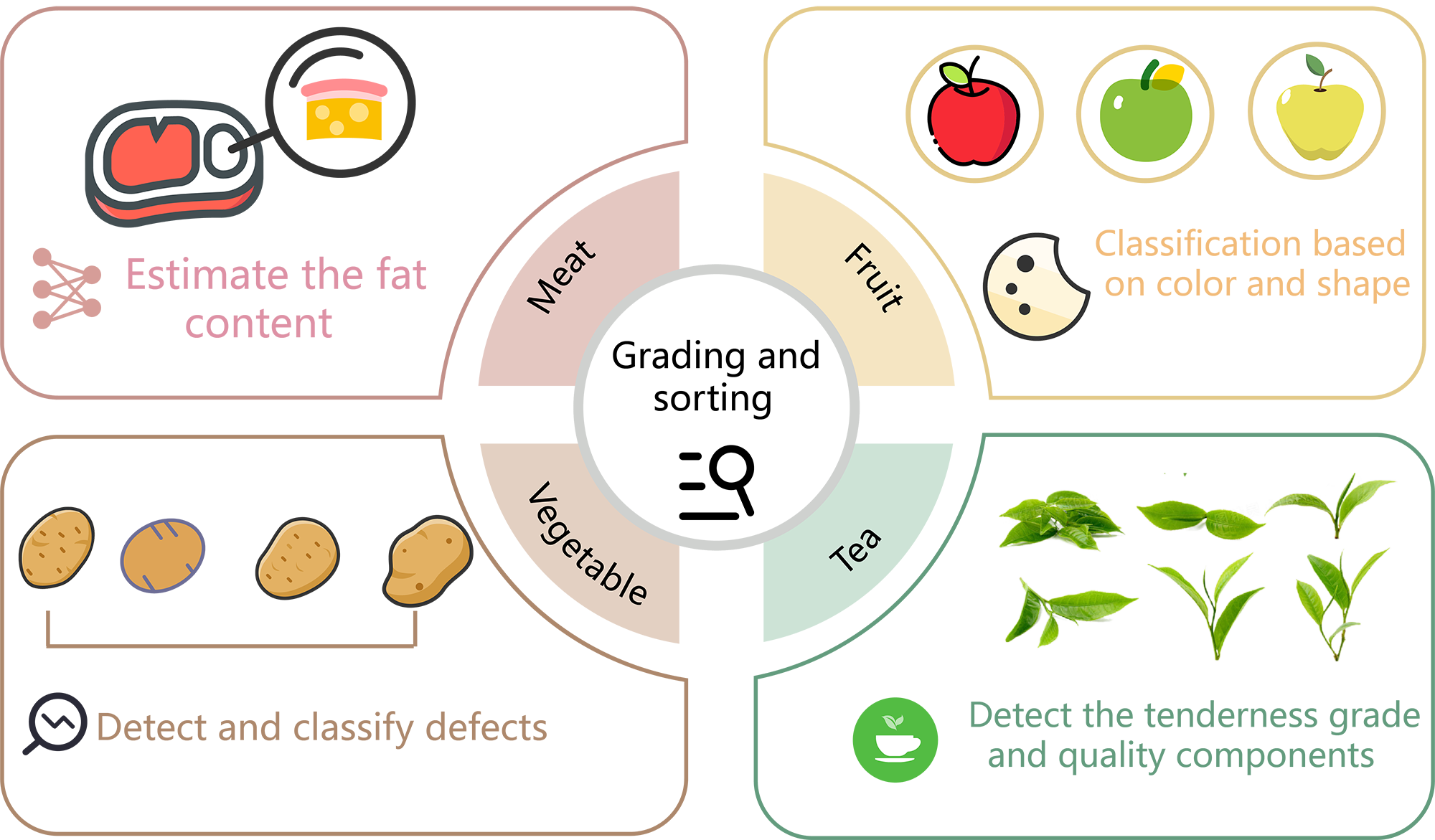

In food processing, raw material grading and sorting are fundamental for maintaining product quality and production efficiency. AI technology's continuous evolution has significantly transformed this process. Figure 1 illustrates the diverse applications of AI in raw material grading and screening, ranging from automated classification to quality evaluation of various food items, including fruits, vegetables, meats, and grains. By integrating advanced image processing, sensor technologies, and data analysis algorithms, AI can swiftly and precisely identify visual attributes, maturity, nutritional value, and potential defects in food items, enabling efficient and accurate grading and sorting. These technologies not only improve production efficiency, but also enhance food processors with a more reliable means of quality control, laying a solid foundation for subsequent processing stages.

ML is also used to predict intramuscular fat content for meat classification and sorting. Traditional methods for detecting intramuscular fat content (IMF%) are accurate but involve lengthy preprocessing. Chen et al. [19] employed visual scores of marbling in loin muscle pictures and traditional meat quality traits as predictors to predict IMF% in pigs, utilizing computer vision methods and meat quality attributes. Compared to traditional techniques, the duration was significantly shortened. used partial least squares (PLS) and ML analysis methods. They measured 299 lamb loins using a near-infrared fiber-optic device. Excised samples were used for Soxhlet extraction to determine IMF content, and predictive models were developed using PLS or ML analysis. The predictive models' outcomes for IMF were comparable between the two analytical techniques and successfully predicted intramuscular fat levels in lamb muscle [20]. Robots [21] designed for sorting are capable of categorizing fruits according to their color and size. ML can also classify fruits based on their colour, shape, and so on. Phate et al. [22] proposed various SVM classifiers and a weighting model developed using Optimized Adaptive Neuro-Fuzzy Inference Systems (ANFIS) and the Computer Vision System (CVS), achieving automatic classification of sweet lemon fruits. The model is also highly reliable for estimating sweet lime weight. Kumar et al. [23] proposed a system using two SVM classifiers for automated evaluation and categorization of tomatoes. Tomatoes were classified in three stages. In the first stage, tomatoes are distinguished from other species. In the second phase, mature and immature tomatoes are categorized based on their color. Stage three identifies three varieties of anomalies: black spots, ulcers, and melanin. The system's efficacy was assessed based on its precision, exactness, perceptiveness, and precision indices. Comparative analysis with similar methods proved that the suggested system outperforms current ones in classifying and grading tomatoes.

DL, with its focus on multi-layer neural networks, finds broader application in the automated categorization and sorting of raw materials. Pan et al. [16] produced a new framework called DeepFood. First, deep feature extraction was performed using CNN-based transfer learning algorithm. Then, an algorithm for classifying multiple categories was employed. Assessment of the DeepFood framework on a diverse dataset revealed its enhanced capability in identifying ingredients, surpassing numerous existing studies in the domain. The process involves more than just employing DL for the extraction of diverse and efficient features from the food ingredient image dataset, but also by applying advanced ML techniques to improve the average accuracy of classification. DL is widely used for fruit classification, Bhat et al. [24] used DL techniques combined with DT to classify coconuts. Experimental findings indicate a 93% accuracy rate for DT and a 100% accuracy rate for the sophisticated DL model DenseNet. It shows that DL models such as DenseNet perform better compared to traditional ML algorithms such as DT. Different industries use different types and parts of coconuts, so automatic classification of coconuts will help speed up the process. Albarrak et al. [25] utilized CNN for categorizing date fruits. They proposed a new model based on DL and CNN for date fruit classification. The suggested model undergoes training and validation procedures utilizing an internally curated dataset, which encompasses eight distinct varieties of date fruits prevalent in Saudi Arabia. For enhanced precision, the model employs various preprocessing methods, including attenuation learning rate, image enhancement, model checkpoints and hybrid weight adjustment. The model uses the trained MobileNetV2 architecture and the results show that the model attains an accuracy of 99%. This model also undergoes comparisons with other established models like AlexNet, ResNet, VGG16, and so on. The findings demonstrate the superiority of the suggested model over others in accuracy metrics. Momeny et al. [26] employed modified CNN algorithm for the precise identification and classification of cherry appearances. By integrating techniques of maximum pooling and average pooling, it is utilized to improve the ability of CNN generalization, which in turn enables the grading of cherries. The method is also compared with CNN and baseline pooling approaches. The findings reveal that the proposed CNN in the study outperforms the other methods, achieving an impressive accuracy rate of 99.4%. Thus, the application of CNNs in conjunction with image processing techniques offers a promising solution for assessing the export potential and marketability of cherry fruits, potentially serving as a viable alternative to traditional cherry grading methodologies. Hu et al. [27] developed a device for identifying and classifying apples in the field through the DL framework. Utilizing machine vision and various techniques, they developed detection algorithms to distinguish among four characteristics: apple size, color, shape, and surface imperfections. Subsequently, the four characteristics were merged, and SVM was employed to classify the field apples into three categories: first, second, and other-grade fruit. Field studies have demonstrated that, under conditions where the feeding interval for apples is maintained at under 1.5 seconds and the movement velocity does not surpass 0.5 meters per second, the resultant mean grading accuracy attains 94.12%. This level of accuracy fulfills the stringent criteria for on-site apple grading, indicating the efficacy of the adopted methodology. Except apple, CNN models in DL can recognise most fruits , and distinguish those that have rotted from fresh fruits [28]. Motivated by a number of traditional CNNs, Xie et al. [29] introduced CarrotNet, a streamlined model leveraging machine vision and DCNN for the detection of defective carrots. The model, when evaluated on a test dataset, exhibited an impressive accuracy rate of 97.04%. These results underscore its potential application in real-time monitoring and grading of carrot external quality, thereby significantly enhancing operational efficiency and minimizing manual labor requirements. Jahanbakhshi et al. [30] employed a refined CNN algorithm for identifying noticeable flaws in sour lemon fruits, categorizing them based on these flaws. They compared the proposed model with algorithms such as KNN, SVM, DT and ANN classification. The findings indicate that CNN has 100% accuracy. Thus, it's evident that the CNN technique and image processing prove highly efficient in the classification of sour lemons. The use of DL extends far beyond the realm of fruits. For example, in nuts, Taner et al. [31] employed a CNN model for the categorization of hazelnut types. The precision of the suggested model reaches up to 98.63% in the test dataset comprising 510 images. This outcome suggests indicates that the suggested model can accurately classify hazelnut varieties to meet the need for non-destructive, fast, and reliable classification for commercial hazelnut production. In meat, CV methods combined with ANN enable real-time non-destructive monitoring. Taheri-Garavand et al. [32] employed a hybrid Artificial Bee Colony-ANN algorithm for selecting the optimal features after feature extraction from preprocessed fish images. Finally, SVM, K-NN and ANN algorithms which are commonly used methods were used to categorize the fish images. The ultimate findings indicate that the ANN classifier exhibits a strong capability in assessing the freshness of carp preserved in ice. This underscores the applicability of the ANN approach in such contexts. DL can be used to predict carcass cut yield, and the use of CNN in carcass segmentation can also be used for carcass grading to determine meat quality, Matthews et al. [33] trained DL models for forecasting carcass cut yields and assessed these predictions against more traditional ML techniques. Their findings revealed that while convolutional neural network (CNN) models could indeed predict carcass cut yield, the method using carcass sizes in the ML algorithm was slightly better in absolute terms [34] assuming a crucial position.

Table 1 illustrates the use of ML and DL for categorizing and sorting other products. It can be asserted that the implementation of DL and ML has permeated almost all facets of the food sector, assuming a crucial position.

| Products | Species | Type | Results | Reference |

| Vegetable | Potatoe | DL and multispectral imaging | Detect and classify defects | [35] |

| Bell pepper | ANN | Automated sorting | [36] | |

| Tomato | DL and CV | Detect external defects | [37] | |

| Citrus | CNN | Real-time sorting and weight grading | [38] | |

| DL and CV | Fast in-line sorting | [39] | ||

| Mulberry | ANN and SVM | Classify the ripeness | [40] | |

| Apples | DL | Identify and classify the ripeness | [41] | |

| CV | Identify rotten apples from fresh ones | [42] | ||

| Other | Tea | SVM | Detect the tenderness grade and quality components | [43] |

| Beverage | CNN | Classify | [44] | |

| Rice | CNN | Classify damaged rice | [45] | |

| Mushroom | CNN | Classify poisonous and edible mushrooms | [46] |

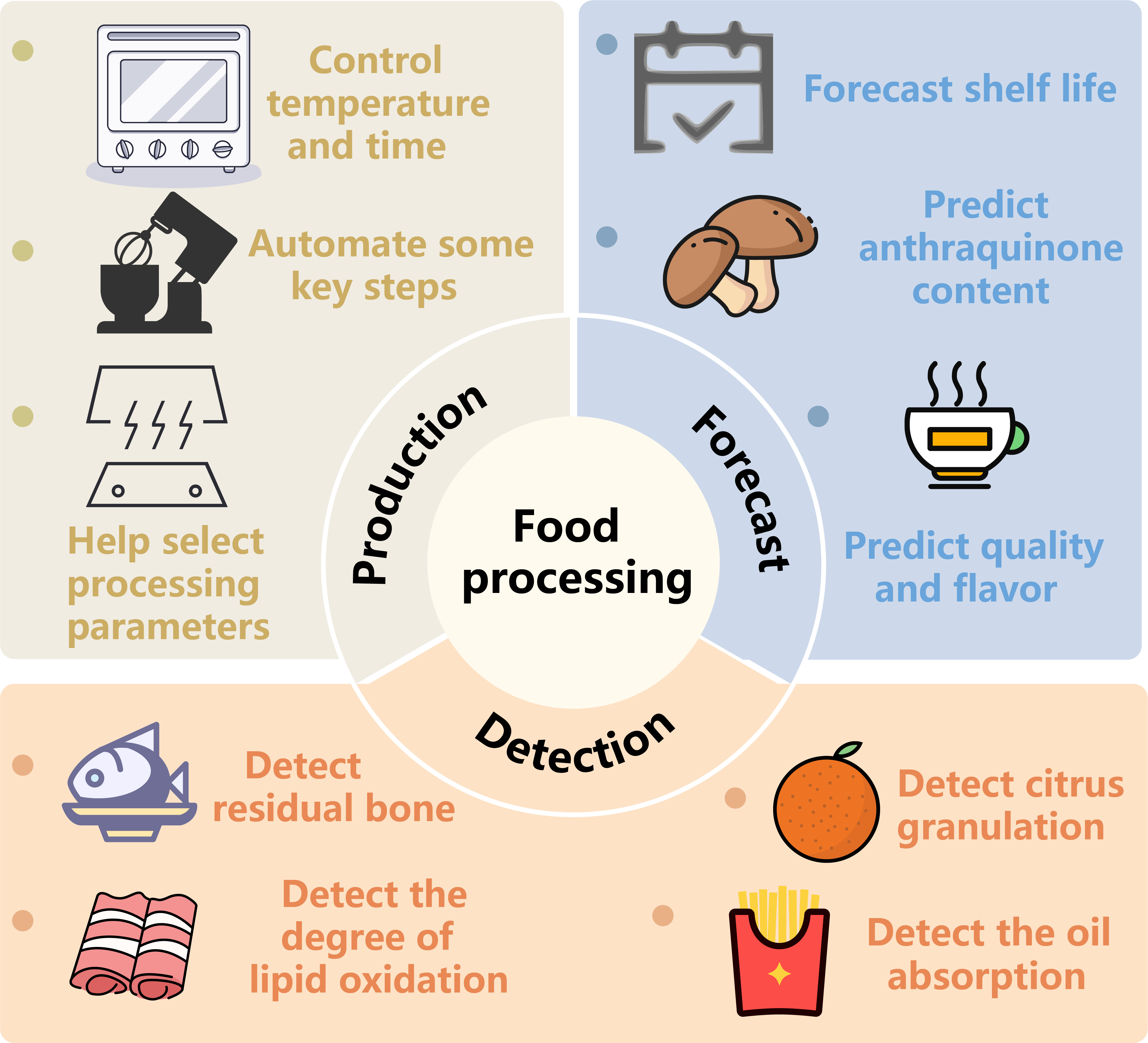

In food processing, AI technology not only improves production efficiency but also significantly enhances food safety and quality assurance. Figure 2 illustrates the extensive applications of AI in food processing and production, ranging from parameter optimization to automated production. Through the integration of sophisticated sensing technologies and advanced image processing techniques, AI facilitates real-time monitoring and adjustment of production procedures. This ensures the preservation of essential nutrients in food products while concurrently enhancing production efficiency and elevating product quality standards.

In the realm of food processing, AI plays a pivotal role in selecting appropriate processing parameters, tailored to the microbiological profile of the food items concerned [47]. AI technologies can also enhance pasteurization processes' efficiency and efficacy. Specifically, ML algorithms are employed to monitor product temperatures and heat treatment durations, thereby calculating the actual sterilization effect achieved. Subsequently, these algorithms adjust pasteurization temperatures and durations to ensure the elimination of harmful bacteria and pathogens, while simultaneously preserving the nutritional integrity of the food [48]. Samodro et al. [49] proposed a FL-driven temperature regulation mechanism specifically designed for coffee roasters. The system controls the temperature according to the required degree of roasting. To ensure precise temperature monitoring, a thermal imaging camera is strategically positioned within the roasting chamber to capture the real-time heat distribution of the roasting coffee beans. This camera is seamlessly integrated with a mixing apparatus that facilitates uniform heat distribution among the beans. Integrating this advanced system into the coffee roasting process consistently maintains the quality and aroma of the final coffee product at optimal levels. During the production of baked goods, AI can help automate some of these key steps, such as waking and rising and kneading [3]. AI technology can also greatly improve productivity and product quality in meat processing [4]. For example, in beef carcass cutting systems, sensors combined with computer-controlled cutting produce accurate carcass images. In waterjet automated skinning systems for fish fillets, computerized algorithms determine the optimal trimming pattern [50]. Ozturk et al. [51] combined ML with near-infrared spectroscopy (NIR) to classify food powders under motion conditions, preventing incorrect powder materials from reaching the production line. Their research endeavor involved a comparative analysis of two NIR sensors, each characterized by distinct wavelength ranges. These sensors were utilized to gather data, which was subsequently fed into an ML model tasked with classifying 25 distinct food powder materials. The results show that pre-processing using an autoencoder followed by SVM for all spectral wavelengths of the two sensors gives the most accurate results.

Employing sophisticated AI methods like ML and DL, combined with additive manufacturing techniques, facilitates swift, personalized production and superior quality production [52]. Silva Cotrim et al. [53] developed an approach to classify different phases of bread baking by observing color variations in bread. This approach utilizes a combined system (HS) integrating CNN and SVM. Studies show that the HS CNN-SVM system can independently pinpoint and categorize baking phases without human involvement, surpassing models dependent only on CNN. Moreover, the HS CNN-SVM diminishes the need for memory use and quicker convergence, rendering it ideal for both mobile and embedded systems. Lastly, the HS CNN-SVM maintains its ability to extract color map elements from CNN, facilitating the development of processing control systems in the food sector, especially those related to color discrepancies. ANN also have numerous applications in the field of food processing, including processes such as extraction, drying, filtration, canning, baking, and others. They have proven to be a valuable tool for predicting outcomes with a high degree of accuracy [15]. In the coffee industry, ANN can also be used to identify coffee berries, which can help coffee producers reduce the rate and instances of defects while increasing the quantity of the final product. Fuentes et al. [54] Employed neural networks and artificial vision to recognize coffee fruits. The DL algorithm was trained using 196 images and was able to correctly classify in 41/42 tests with 97.6% efficiency. Nazari et al. [55] combined artificial neuro-fuzzy system with other algorithms. The proposed model predicted the effect of design parameters (including cooking panel location, bread cooking duration, and weather conditions) on the causal parameter (i.e., the desired temperature of the solar bread oven). They further investigated and developed a technique for making flat breads using a solar stove. Fabani et al. [56] developed an ANN model applied to the production of flour from watermelon pomace, specifically focusing on the dehydration/drying process. This model can help optimize the production process and potentially improve the quality and yield of the flour. Sadhu et al. [57] integrated ANN with differential evolution (DE) and simulated annealing (SA) algorithms to optimize cooking parameters for fried fish, with the aim of enhancing its nutritional composition. The experimental results showed that this two algorithms were effective in improving the nutritional parameters of fried fish, specifically the -3/-6 and cis/trans-fatty acid ratios, by 33.18% and 79%, respectively. This experiment's AI modeling and the parameter adjustment technique, rooted in optimization principles, are adaptable for diverse food processing engineering studies, underscoring AI's extensive effectiveness in enhancing food production.

Zhou et al. [58] explored peanut protein content prediction through ML modeling of spectral images and chemical measurements. This approach yielded greater predictive precision and reduced the time spent on fitting compared to conventional ML algorithm models, indicating that blending spectral imagination could be effective. Within the realm of tea studies, Wang et al. [59] merged NIR spectroscopy with in-house CV for forecasting the levels of tea polyphenols and catechins during the processing of black tea. Their research revealed that this combined spectroscopy and imaging approach improved the prediction precision for polyphenols, thereby surpassing previous challenges. Furthermore, both the indicator displacement array (IDA) and the SVM regression method are effective in precisely forecasting crucial tea polyphenol elements in the fermentation process [60].

CNN is capable of predicting fruit production. Behera et al. [61] enhanced the fruit detection efficiency of the initial Faster R-CNN (FR-CNN) through adjustments to the joint intersection over union (IoU) metric. The revised IoU (MIoU) now focuses more on concurrent zones, tackling the shortcomings. Mu et al. [62] developed a tomato recognition system employing DL methods for autonomously spotting whole green tomatoes, no contingent on their shade or developmental phase. This tomato detection model identification model, integrating R-CNN and ResNet-101, showed impressive performance with a dataset, securing an average accuracy of 87.83% and high effectiveness in tomato counting. This indicates the method's applicability in both ripening and predicting yields. Zhang et al. [63] combined spectral imaging methods with deep convolutional generative adversarial networks (DCGAN) to estimate the oil composition of separate corn kernels. DCGAN was utilized to enhance spectral and oil content data at once. A pair of models, Partial Least Squares Regression (PLSR) and SVR, were developed to compare their efficacy pre and post data augmentation. The outcomes reveal that this approach not only boosts the efficiency of both models but also reduces the requirement for extensive training data. Simply put, it facilitates quick and non-invasive forecasting of the oil levels in single corn kernels, regardless of the significance level. Yang et al. [64] developed and tested a smart model using ANN to predict the levels of anthraquinones and antioxidant effects of co-fermentation products from a mix of two or three fungi. The researchers deployed back propagation (BP) and radial basis function (RBF) algorithms for this aim. After empirically assessing anthraquinone levels, it was found that the RBF ANN algorithm showed reduced average absolute and average bias errors relative to the BP ANN algorithm. This approach enhances the composition of mushrooms and betters their anthraquinone levels and antioxidant properties. ANN models are capable of accurately forecasting pH levels during cheese fermentation with just the right amount of data. Li et al. [65] integrated ANN with a mechanistic model to characterize the variances in biomass, lactose levels, and lactic acid concentrations. They addressed the problem of reduced process efficiency in cheese cultivation, a consequence of notable discrepancies in the final stages of various fermentation periods. The suggested hybrid model can precisely forecast pH levels during cheese fermentation with scant data. This study's results can foresee fermentation's conclusion and facilitate further planning, enhancing process efficiency.

Indeed, the role of AI technology is pivotal in regulating the quality of baked products, ensuring inspection accuracy and hygiene. Utilizing AI, producers are capable of autonomously verifying the dimensions, volume, and form of baked items, bypassing manual handling. This process not only improves output but also upholds superior hygiene and product quality during manufacturing [3]. Mavani et al. [66] demonstrated the potential of AI in the food industry by suggesting a fuzzy algorithm to calculate preservative levels in refined fruits. Their research compared this algorithm with the Takagi-Sugeno-Kang (TSK) approach, revealing that fuzzy logic surpassed TSK in these particular tasks. This indicates that fuzzy logic is a highly suitable technique for accurately determining the percentage of food preservatives. This accuracy is crucial for ensuring both the safety and quality of processed foods. In the case of meat items, blending ML and NIR-HSI offers a swift and non-harmful approach to assessing the level of lipid oxidation in lamb meat. Fan et al. [67] created PLSR and Least Squares Support Vector Machine (LSSVM) models to align entire spectra with the assessed values of thiobarbituric acid reactive substances (TBARS). The study's findings indicated that the refined LSSVM model, employing eigenbands chosen via the CARS, successfully forecasted the levels of TBARS. This implies the potential of NIR-HSI in a rapid and non-invasive measurement of lipid oxidation in mutton, thus confirming its practicality for use in these contexts. developed a detailed predictive model for tracking moisture variations in tea by merging machine vision with near-infrared to analyze the processing of green tea. The findings revealed that a blend of intermediate data fusion that integrates insights from machine vision and NIR can precisely identify moisture levels in this procedure. This approach is highly significant as it addresses the issue of low prediction accuracy associated with using a single sensor alone [68]. Wang et al. [69] combined SVM model with NIR, electronic eye and colorimetric sensing to assess leaf withering in black tea processing. They used a micro-spectrometer, custom machine vision, and colorimetric array to capture data. Comparing low-level and mid-level data fusion strategies, the SVM model combining all techniques performed best, with mid-level fusion outperforming low-level. The highest SVM model accuracy was 97.50%, demonstrating a cost-effective, non-destructive method for evaluating black tea wilting. While Jin et al. [70] combined the SVM model with Fourier Transform Near Infrared Spectroscopy and CVS to achieve a rapid assessment of black tea fermentation. The study integrates the advantages of Fourier transform NIR and computerized visible spectroscopy through a mid-level fusion approach. The results obtained from this integrated method surpass those achieved using any single method alone for evaluating black tea fermentation. It is demonstrated that combining Fourier transform NIR and principal component analysis feature extraction, within a mid-level fusion strategy, provides an effective and swift means to assess the degree of black tea fermentation.

| Products | Species | Type | Results | Reference |

| Meat | Cod | ML | Predict liquid loss | [76] |

| Chicken sausages | CV | Predict meat traits | [77] | |

| Pork | ML and HSI | Assess the content of monounsaturated and polyunsaturated fatty acids | [78] | |

| Salmon | CV | Detect residues | [79] | |

| Machine vision-based neural network | Detect residual bone | [80] | ||

| Fruit | Mango | SVR | Predict the shelf life | [81] |

| Other | Coffee | ANN and EN | Predict quality and flavor | [82] |

| Garlic | ANN | Predict optimal drying conditions | [83] | |

| Raw milk | ML | Detect antibiotic residues | [84] |

Based on DL, Jie et al. [71] developed a rapid and non-destructive technique for detecting citrus granulation. Their study constructed various models using preprocessed transmission spectra derived from hyperspectral imaging as input data. Among these models, the CNN demonstrated the highest training accuracy of 88.02%, outperforming both the Back Propagation Neural Network (BP-NN) and the Least Square Support Vector Machine (LS-SVM). Furthermore, after incorporating a batch normalization layer into the CNN, the experimental results revealed that the detection model achieved remarkable accuracies of 100% and 97.9% on the training and validation sets, respectively. Using hyperspectral transmittance images (HSTIs) and a DL-based fully convolutional network (FCN) approach, internal bruising in blueberries can be accurately detected even after mechanical damage. The outcomes of the tests reveal that using the DL technique, segments of bruises and calyx terminals (blueberry's stem) can be successfully isolated from the fruit within 30 minutes after damage, proving its proficiency in identifying internal blueberry bruises [72]. Zhao et al. [73] developed a methodology employing visible/near-infrared spectroscopy (vis-NIR) and Artificial Neural Networks to measure bacterial levels in real-time throughout the kombucha fermentative procedure. The team formulated and refined three varieties of AI models: BP-ANN, Extreme Learning Machine ANN, and RBF-ANN models, which utilizes meta-heuristic algorithms specifically for this. After optimization, the ANN models were significantly improved, with RBF-ANN having the best results. The findings suggest that this online detection method can be effectively used to monitor the bacterial concentration in kombucha, providing a viable strategy for the real-time monitoring of specific indicators during food fermentation processes. Wang et al. [74] developed two intelligent models, PLSR and BP-ANN, for accurately detecting the oil absorption of French fries based on their surface features. The prediction set coefficients for both the PLSR and BP-ANN models exceeded 0.93, suggesting that the integration of surface characterization and chemometrics offers a swift and precise method for determining the oil content in French fries. And experiments show that CNN-based features show better performance than manual features or features extracted by ML algorithms, showing great potential. Liu et al. [75] combined CNN with NDT techniques and CVS to achieve effective and efficient detection and analysis of complex food matrices. They found that traditional ML algorithms relying on handcrafted features have limited capabilities and generally perform inferior to this combined approach.

In addition to the above, Table 2 showcases the application of ML and DL in various other products, demonstrating the widespread use of these technologies across different fields.

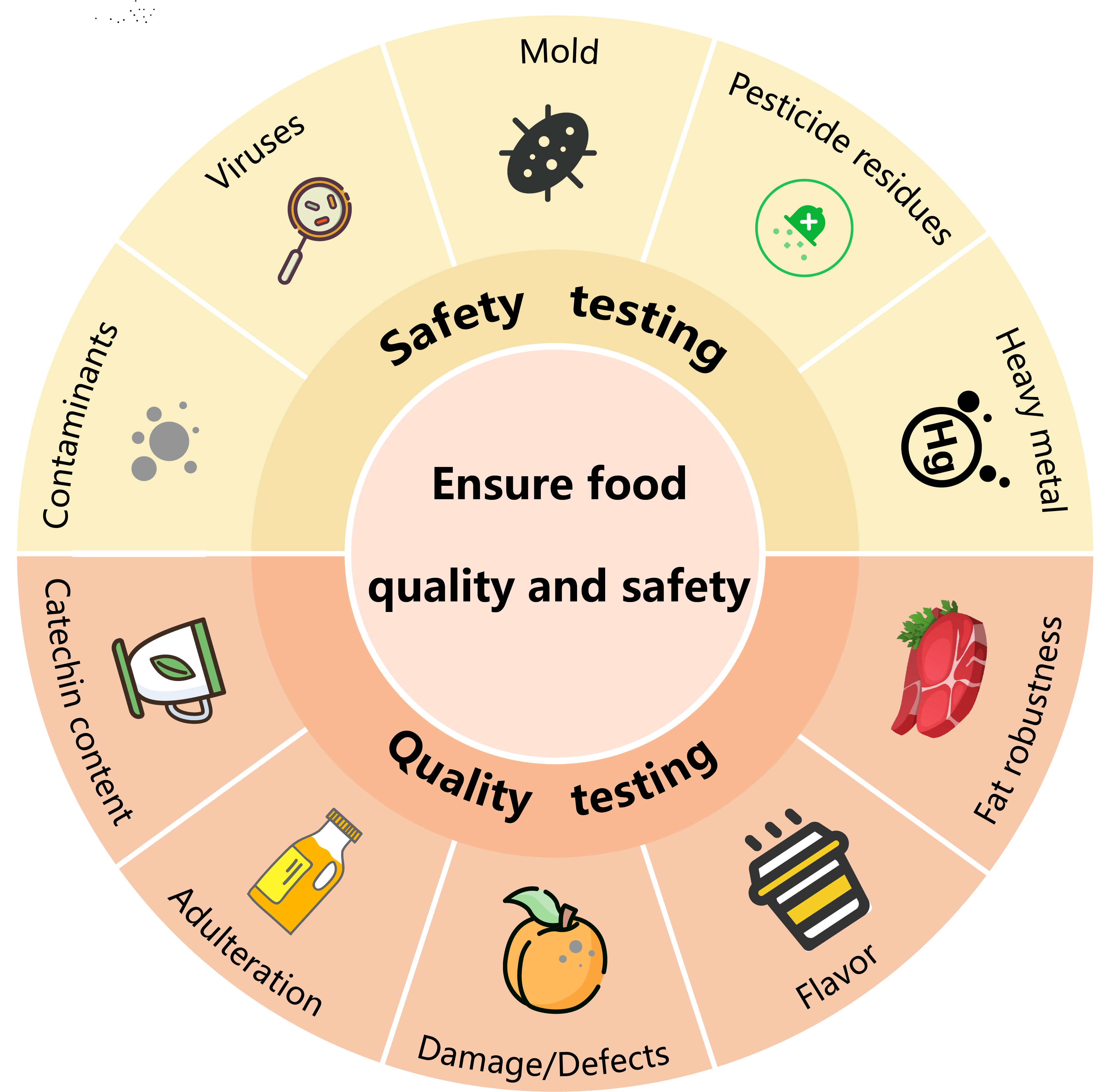

The core concerns in the food processing sector are food safety and quality. AI technology offers strong support for food quality monitoring and safety testing via rapid, non-destructive detection methods. Figure 3 summarizes several AI applications in ensuring food safety and quality, including pathogen detection, food adulteration identification, and quality indicator prediction. These technologies can not only swiftly detect potential food safety hazards but also ensure food safety and superior quality throughout production, processing, and storage phases through real-time monitoring and preemptive alerts.

ML can utilize readily available data to predict food insecurity and issue early warnings [85]. By utilizing CVS and ML, physical contaminants in food (such as foreign objects or particles) can be identified, thus preventing contaminated food from entering the market and reaching consumers. Additionally, AI algorithms can analyze DNA and RNA sequences, enabling the accurate identification and classification of pathogens that cause foodborne illnesses. This is essential for ensuring food safety [86]. Wang et al. [87] effectively utilized ML to identify various food pathogens. They developed a cell-printed electrochemical impedance sensor capable of both qualitative and quantitative identification of three pathogens: Escherichia coli, Staphylococcus aureus, and Vibrio parahaemolyticus. Scientists derived six distinct parameters from electrochemical impedance spectroscopy (EIS), forming a dataset that served as the key inputs for the ML model. They selected and refined the Random Forest (RF) algorithm to develop a bacterial classifier capable of recognizing and detecting three types of bacteria. Furthermore, by applying normalization-weighted concentration classification, they achieved highly accurate, efficient, and effective identification of samples from the original dataset, unattributable sources, and actual samples. This promising, simple, and direct detection approach is crucial for the quick identification and diagnosis of harmful bacteria in food safety applications. Du et al. [88] proposed an innovative technique for identifying and classifying foodborne pathogens. This method integrates Raman spectroscopy with Generative Adversarial Networks (GAN) and multi-class SVM. This approach addresses the issue of requiring numerous samples for training by using GAN to generate artificial data, thereby enhancing the training dataset.

The integration of GAN and SVM improves the precision of detection and classification. This integration offers an innovative approach to bacterial identification, enhancing food safety by streamlining and improving the precise recognition of foodborne pathogens [88]. Whole-cell biosensor arrays based on ML prediction models can accurately monitor mold contamination in foods. Ma et al. [89] created an innovative whole-cell biosensor array to track mold contamination in food sources. The optimal classifier identified through the comparison of six machine learning algorithms. Utilizing the RF classifier, they attained a perfect 100% accuracy rate in differentiating between healthful peanuts and corn. Moreover, distinguishing infected peanuts from corn prior to molding was 95% and 98% accurate, respectively. Sparse partial least squares decision analysis showed an 83% success rate in identifying moldy peanuts versus corn. Utilizing sparse partial least squares decision analysis, an 83% accuracy rate was recorded in differentiating moldy peanuts from moldy corn. The findings indicate that integrating the whole-cell biosensor array with an ML classifier results in superior precision and usability in managing food molds. Liu et al. [90] utilized MSI alongside diverse ML strategies to swiftly identify zearalenone (ZEN) in corn, employing a genetic algorithm and GA-BPNN to pinpoint wavelengths most closely linked with ZEN concentrations in corn. The GA-BPNN technique attained a 93.33% accuracy rate in identifying levels of contamination in ZEN. The results imply that combining multispectral imaging with ML is an effective method for quick tracking of ZEN levels in maize, presenting a hopeful resource for the food safety sector. Jiang et al. [91] employed hyperpectral NIR in tandem with PLSR for identifying Pseudomonas spp. and Enterobacteriaceae, key agents in spoilage during the cold storage of chicken meat to swiftly evaluate the spoilage level. In their research, the spectra were pre-processed using a standard normal variate (SNV), Savitzky-Golay convolutional smoothing (SGCS), and multiplicative scattering correction (MSC), spanning a complete wavelength spectrum of 900-1700 nm. These pre-processed spectra were then correlated with the total counts of Pseudomonas spp. and Enterobacteriaceae bacteria (PEC) in fresh chicken breast meat, employing the PLS algorithm for swift forecasting. The outcomes showed that the MSC-PLS model, developed with spectra preprocessed through MSC, outperformed the PLS models developed using different spectra. The study concluded that using both NIR spectroscopy and the PLS algorithm for quick and harmless identification of PEC in chicken meat is efficient. Li et al. [92] engineered adaptable paper-based surface-enhanced Raman scattering (SERS) detectors to amplify the Raman emission of chloramphenicol from food specimens. Additionally, they crafted an AI-based prediction framework for the swift identification of chloramphenicol in food items. Within the array of AI instruments used, the multivariate scattering correction integrated adaptive weighted PLS model demonstrated superior predictive efficiency. The analysis of actual samples showed recovery rates between 90% and 102%, featuring a 3.3% RSD. This data suggests that the SERS sensor, in conjunction with the AI forecasting model, is rapid, consistent, and dependable in identifying chloramphenicol residues in food samples. In addition to rapid identification of pathogens, combining face recognition technology with ML methods can detect heavy metal mercury stress in tobacco plants [93].

DL has gained widespread application in food germ identification. Park et al. [94] utilized the automatic segmentation of foodborne bacteria in chicken rinses using DL and image processing techniques. This advanced technology offers accurate and robust automated segmentation, which facilitates the detection of pathogenic bacteria using FPI-HMI. Significantly, this method markedly decreases the duration from raw hypercube capture to categorization by 15 seconds. It not only simplifies the identification process but also improves the efficiency of food safety surveillance. Identifying the proliferation of Aspergillus flavus in peanuts through ANN and SVM. Ziyaee et al.'s [95] research involved analyzing peanut seed images treated with Aspergillus flavus via three distinct ML instruments: SVM, ANN, and ANFIS. The findings revealed that ANN's precision in identifying fungal proliferation in peanuts carrying Aspergillus flavus infection post-72 hours reached 99.7% with a distinct color backdrop and lighting. ANFIS demonstrated an impressive 99.9% precision in identifying fungal proliferation on peanuts within a mere 48-hour period of Aspergillus flavus infection. The outcome unmistakably demonstrates the efficacy of ML methods in identifying the presence and proliferation of Aspergillus flavus in peanuts, establishing its importance in food safety and quality assurance. Gao et al. [96] developed a strategy utilizing HSI and 1D CNN-based for rapid and accurate analysis of aflatoxins in cereal crops, particularly peanuts and maize. Their research also involved an assessment of the 1D-CNN's efficacy against feature selection and various other techniques. The results indicated that neural networks significantly enhanced detection efficiency compared to feature selection. This study is of positive significance for pre-production detoxification in food processing and foreign trade enterprises. DL algorithms can also utilize metabolomics data to rapidly detect pathogenic and non-pathogenic microorganisms. Wang et al. [97] apply DL algorithms to achieve rapid detection of both pathogenic and non-pathogenic microorganisms through the utilization of metabolomics data. The study revealed that the ANN achieved an average accuracy of 99.2% in predicting unknown microorganisms in a controlled laboratory environment. When compared to other prevalent data analysis methods, such as the RF Model and SVM, the ANN consistently outperformed them, highlighting the substantial potential of deep learning in metabolomics data analysis. Kolosov et al. [98] used multispectral imaging and deep CNN to estimate microbial populations in meat samples. The DL models were run on an embedded platform and the researchers used different meat sample storage conditions and evaluated various DL models and embedded platforms. Experimental results indicate that the XavierNX platform excels in latency and throughput, whereas the Nano and RP4 platforms offer advantages in efficiency and cost-effectiveness, respectively. DL is additionally applicable in identifying residues, as demonstrated by its integration with SERS and a 1D-CNN, enabling swift characterization of pesticide residues in tea. In relation to conventional identification techniques like SVM, PLS-DA, K-NN, and RF, the 1D-CNN approach showed enhanced precision, reliability, and sensitivity in identification. In summary, this innovative analytical method capitalizes on the advantages of SERS and the DL technique (1D CNN), offering a hopeful solution for quickly detecting pesticide remnants in field tea leaves [99]. Seo et al. [100] combined 1D-CNN, near-infrared HSI, and DL technology to carry out non-invasive identification of organic residues in vegetables. The outcomes of the experiments showed that the efficacy of the 1D-CNN method was superior to the validation precision realized by the SVM classifier. As a result, employing near-infrared imaging along with DL techniques offers possibilities for swift and harmless identification and categorization of organic matter in food processing sites. Sha et al. [101] employed SERS in conjunction with CNN for rapid identification of benzodiazepines (diazepam and midazolam). They trained the CNN for both qualitative and quantitative identification of these two drugs in water and beverage samples. The proposed method creates an intelligent identification model for SERS spectra, leveraging DL techniques. This model allows for a rapid and sensitive differentiation between the two benzodiazepine drugs. Salam et al. [102] developed three classification algorithms utilizing Linear Discriminant Analysis (LDA), SVM and ANN methods to detect immature seeds and foreign matter in chickpea mixtures. ANN and LDA outperformed SVM in terms of classification accuracy of detection. The image processing techniques developed in this study can be incorporated into vision-based real-time systems, and the newly devised algorithms are effective in identifying undesirable elements, such as foreign objects and ripe chickpea kernels, within chickpea mixtures.

ML can be effectively used for food quality monitoring. For example, Sánchez et al. [103] used ML techniques in conjunction with CVS to perform multivariate analysis of beef color variation and thus determine beef quality. By utilizing CVS to capture the beef slices' color, the researchers tested the predictive capabilities of three classifiers: DT, logistic regression, and multivariate normal distribution, in distinguishing between fresh and non-fresh beef colors. The outcomes revealed that all three models demonstrated high accuracy. These findings emphasize the superiority of multivariate analysis in predicting beef color over the conventional method of analyzing each color channel independently. AI is indeed extensively utilized in the realm of tea quality inspection, often in conjunction with diverse techniques. Tang et al. [104] illustrate this by employing a combination of first-order derivative (FD), principal component analysis (PCA), and SVM to construct a discriminant model specifically designed for the recognition of tea leaf quality grades. In the training set, an outstanding 98.2% accuracy was achieved, and this impressive performance continued with a remarkable 98.2% in the test set. These findings clearly illustrate the effectiveness of the FD-PCA-SVM model in recognizing and presenting tea quality distinctions. Moreover, the research highlights the appropriateness of hyperspectral imaging technology in evaluating the quality of green tea. Ren et al. [105] employed near-infrared HSI and multiple DT methods in ML to accurately identify and grade the quality of black tea. Their study contrasted three unique supervised decision tree algorithms: fine, medium, and coarse. The findings indicated that the fine tree model, grounded in data fusion, exhibited the most superior predictive capabilities. During the prediction phase, this model demonstrated an impressive correct classification rate (CCR) of 93.13% when assessing black tea quality. The study highlights that combining human-computer interaction methodologies with intelligent algorithms constitutes a rapid and effective approach for precisely identifying the grade quality of black tea. Li et al. [106] conducted a study to both qualitatively and quantitatively evaluate the fermentation quality of black tea using HSI. Their research findings revealed that the developed model could successfully distinguish the degree of fermentation, achieving a correct classification rate of 83.33% for the prediction set. Moreover, the quantitative predictive model showcased exceptionally high accuracy in projecting catechin levels. This research conclusively illustrated the practicality of leveraging hyperspectral imaging for assessing the fermentation quality of black tea. Wang et al. [107] iemployed a NIR spectrometer connected to a smartphone for tea quality assessment. The primary objective was to forecast the catechin and caffeine concentrations in both green and black teas. The results of their study revealed that the model based on SNV preprocessing and SVR exhibited precise predictive performance for both catechins and caffeine. They utilized different spectral preprocessing methods in tandem with both linear PLSR and nonlinear SVR to construct precise predictive models [108]. ML can also effectively deployed to swiftly and efficiently detect food adulteration, thereby ensuring the preservation of food quality. Pradana-López et al. [109] introduced an AI-based method for the quick detection of adulterated lentil flour in real-time scenarios. They formulated a mathematical model utilizing CNN and transfer learning, particularly employing the ResNet34 architecture, to discern samples of lentil flour that are tainted with minuscule amounts of pistachios (nuts) or wheat (gluten). Experimental results demonstrated the model's robust performance, showcasing an impressive 99.1% accuracy in misclassifying lentil flour samples that contained ground pistachios, and a 96.4% accuracy in inaccurately classifying samples with wheat flour. These findings underscore the model's efficacy and its prospective utility for two distinct cohorts: individuals diagnosed with celiac disease and those affected by nut allergies. Kalinichenko et al. [110] carried out a study aimed at evaluating the genuineness and identifying any adulteration in soy protein sausages. They integrated EN with chemometric techniques to detect and quantify soy proteins. In their research, they employed the attributes obtained from the EN as input data for refining PNN. Specifically, they extracted area values and maximum response values from the EN readings to serve as features for evaluating and comparing their effectiveness in differentiating between various sausage types. The findings of their study indicated that using the raw maximum response values as input vectors for the PNN resulted in a 100% classification reliability. This meant that the model was capable of accurately classifying all types of sausages without any misclassifications, effectively thwarting label fraud. AI can also be utilized for damage detection purposes. Yang et al. [111] employed an EN method combined with chemometrics to quickly and non-destructively assess if yellow peaches are compromised or intact. They compared various models using samples collected at different time points post-damage occurrence. Their findings revealed that within 24 hours of the peaches sustaining damage, the accuracy in identifying the damaged fruits reached 93.33%. This indicates that the EN has significant potential for detecting compression damage in yellow peaches. Munera et al. [112] found that HSI combined with ML, particularly the XGBoost classifier, demonstrates exceptional effectiveness in identifying typical defects in loquat fruits. Across three different approaches—categorizing fruit pixels as sound or defective, distinguishing internal from external defects, and separately identifying specific defect types—the XGBoost classifier achieved success rates of 97.5%, 96.7%, and 95.9%, respectively. These results highlight the technique's capability to enhance the quality control of loquat fruit. Furthermore, the integration of HSI with PLSR models in ML has diverse applications. It can predict the robustness of intramuscular fat in lambs [113], nondestructively determine the inosinic acid (IMP) content of chicken [114], and detect the freshness of frozen meat in real-time without thawing it out [115]. These capabilities underscore the adaptability and promise of HSIs and ML techniques in the domain of food quality evaluation and management.

| Products | Species | Type | Results | Reference |

| Meat | Pork | ML and HSI | Identify jaw meat adulteration | [121] |

| HSI and PLSR | Detect homologous fats | [122] | ||

| Fish fillets | HSI and DL | Predict total volatile basic nitrogen content | [123] | |

| Vegetable | Oilseed rape leaves | DL and fluorescence hyperspectral | Detect heavy metal lead (Pb) content | [124] |

| Cereals | Corn | ML and HSI | Detect aflatoxin | [125] |

| Other | Tea | SERS | Detect pesticide residues in tea leaves | [126] |

| CNN and PLS and ELM | Detect thiram and pymetrozine | [127] | ||

| SVM and PLS and NIR | Assesse tea quality | [128] | ||

| CVS | Evaluate the quality | [129] | ||

| SVM and MV and HSI | Assesse quality | [130] | ||

| Wolfberry | ANN and GA and RSM | Determine pesticide residues | [131] | |

| Mayonnaise | ML and CV | Quickly screen the quality | [132] | |

| Coffee | EN and ANN | Predict the quality and flavor | [82] | |

| Nut | HSI and DL | Assess quality | [133] | |

| Olive oil | CNN | Detect and quantify adulteration | [134] | |

| SERS and LSTM | Detect phthalates in olive oil | [135] | ||

| Sea cucumbers | SVM and HSI | Detect adulteration of salty sea cucumbers | [136] |

DL also has numerous applications in food quality testing. For example, An et al. [116] successfully applied CNN to detect the wilting humidity of black tea. TThey compared the prediction performance of the CNN model with traditional methods such as PLS and SVR. The results indicated that the CNN-based model, which leveraged confidence intervals for quantitative prediction of dead leaf moisture content, outperformed the conventional models. This demonstrates the power of DL in providing accurate and reliable predictions for food quality attributes, potentially leading to improvements in food safety and quality control. DL can facilitate the detection of quality attributes in roasted coffee beans, including the prediction of their roasting degree [117]. Thazin et al. [118] used EN and ANN to predict the acidity level of freshly roasted coffee. Their study incorporated an array comprising eight diverse semiconductor gas sensors, designed to analyze the aroma of the coffee. The EN was able to clearly categorize the acidity of roasted coffee at different roast levels with nearly identical scoring results to those obtained using artificial neural networks and manual scoring. The study shows that the e-nose has shown the ability to integrate with gourmet robots. Rong et al. [119] used DL and machine vision to perform rapid impurity detection of chocolate. The proposed DL method is simple and effective, which avoids manual feature extraction, not only overcomes the aggregation phenomenon of foreign objects and impurities in the image, but also adapts to the interference caused by wear and tear damages on the surface of the drive belt, and avoids detection errors in the actual factory environment. The outcomes of the experimental analysis indicate that the proposed methodology achieves a high degree of accuracy in segmenting object regions, with a success rate of 99.4% in the test images. Furthermore, it demonstrates robust performance in classifying foreign objects, correctly identifying 96.5% of them in the verification images. Notably, the methodology achieves perfect detection accuracy, with a 100.0% success rate in the test images. These results suggest that the proposed approach holds promise for applications requiring rapid and precise detection of impurities in chocolate products. Kong et al. [120] explored the detection of adulteration in marine fish meal using a combination of near-red light hyperspectral imaging and CNN. Their objective was to quantitatively identify adulterated feather meal and fish by-product meal within the fish meal samples. Additionally, the researchers compared the PLS and SVM models with the proposed CNN model. The comprehensive analysis unveiled that the CNN model outperforms both PLS and SVM in terms of classification and regression tasks. Specifically, the CNN achieves an outstanding accuracy of 99.37% across six classifications. This pioneering integration of NIR imaging and CNN calibration presents a groundbreaking approach to detecting fish meal adulteration with low-cost processed animal proteins, notably fish by-product meal.

Additional examples of ML and DL applications used to ensure the quality and safety of food products are shown in Table 3.

| Abbreviation | Full name | Abbreviation | Full name |

|---|---|---|---|

| AI | Artificial intelligence | CNN | Convolutional neural network |

| ML | Machine learning | NIR | Near-infrared |

| DL | Deep learning | DE | Differential evolution |

| SVM | Support vector machine | SA | Simulated annealing |

| DA | Discriminant analysis | IDA | Indicator displacement array |

| NB | Naive bayes | IoU | Intersection over union |

| K-NN | K-Nearest Neighbors | PLSR | Partial least squares regression |

| GLM | Generalized linear model | BP | Back propagation |

| SVR | Support vector regression | RBF | Radial basis function |

| LR | Linear regression | TSK | Takagi-Sugeno-Kang |

| GPR | Gaussian process regression | TBARS | Thiobarbituric acid reactive substances |

| DT | Decision tree | HSTLs | Hyperspectral transmittance images |

| FCM | Fuzzy C-means | FCN | Fully convolutional network |

| FL | Fuzzy logic | EIS | Electrochemical impedance spectroscopy |

| RNN | Recurrent neural network | RF | Random forest |

| DNN | Deconvolution neural network | GAN | Generative Adversarial Networks |

| FNN | Feed-forward neural network | SNV | Standard normal variate |

| MNN | Modular neural network | SGCS | Savitzky-Golay convolutional smoothing |

| MPNN | Multilayer perceptron neural network | MSC | Multiplicative scattering correction |

| GAN | Generative adversarial network | SERS | Surface-enhanced Raman scattering |

| IMF | Intramuscular fat content | LDA | Linear discriminant analysis |

| PLS | Partial least squares | FD | First-order derivative |

| CVS | Computer vision system | PCA | Principal component analysis |

This review paper has provided a comprehensive overview of the diverse applications of AI, particularly ML and DL, within the food processing sector. By automating raw material grading and sorting, these technologies have enabled more efficient and accurate classification of various food items. In production, AI can optimizes parameters, enhancing food safety and preserving nutritional value. Additionally, the ability of AI to predict and forecast parameters like shelf life, nutrient content, and quality changes has empowered food manufacturers to make informed decisions. Moreover, AI-based detection methods provide rapid and non-invasive ways to evaluate food quality and safety. However, it must be acknowledged that the application of AI in the food industry also has certain limitations. The primary challenge is the difficulty and high cost of acquiring high-quality data. The complexity of the industry leads to time-consuming data collection, and unethical data collection also involves privacy and security issues. Incomplete or inaccurate data can cause model bias and incorrect predictions, potentially impacting quality and safety decisions.

In conclusion, although AI brings innovative opportunities for food processing, addressing its limitations is crucial. There is a need for continuous improvement of ML and DL algorithms to enhance data quality and manageability, research interpretable AI models, and reduce enterprise usage costs. Only in this way can the food industry better leverage AI to meet consumer needs and achieve sustainable development.

The abbreviations and their corresponding full names appearing in the text can be found in Table 4.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. Agricultural Science and Food Processing

ISSN: 3066-1579 (Online) | ISSN: 3066-1560 (Print)

Email: [email protected]

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/iece/