Sustainable Intelligent Infrastructure

ISSN: 3067-8137 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

Natural soil is a material that is both complex and variable. There are variations in soil properties between locations. In addition to depth, loading, drainage, and environmental conditions, there are variations in the black cotton soil properties. There is a mineral identified as montmorillonite, which is present in black cotton soil and is responsible for the shrinking and enlargement observed when the soil is exposed to water. This variation causes numerous geotechnical issues. Approximately 20% of the soil is black cotton soil. There are numerous methods available for improving black cotton loam [1].

The soil stabilization is to strengthen the soil and increase its resistance to water erosion by fusing the soil particles. Additionally, it is used to waterproof particles or two combination procedures. Drainage and compaction are the simplest stabilization methods that enhance the black cotton soil's inherent shear strength [2]. The enhancement of particle size grading the soil can be stabilized by combining binders with weak soils, such as cement, lime, bitumen, and other substances, or through mechanical stabilization. Soil stabilization is performed to obtain necessary engineering characteristics in soft soils (such as clayey peat, silt, and organic soils) [3]. Lime is an inorganic mineral primarily composed of oxides, hydroxides, and calcium carbonates. Cement and lime are the most common stabilizing agents used to improve weak soil characteristics. Solid refuse materials, such as quarry dust and fly ash [4], can also be used to stabilize the soil. Rice husk ash is also utilized, but because it lacks cementitious properties, it cannot be used to stabilize black cotton soil alone. Therefore, it is combined with binders such as lime, cement, lime waste, calcium chloride [5].

Black cotton soils have been regarded as problematic for use in civil engineering applications. These soils have weak engineering characteristics and an unusual swell-shrink response to changes in moisture content. This characteristic transforms these soils unsuitable for all forms of civil engineering construction. In addition, when used in their natural state, these soils have low standards for strength capacity. This characteristic of black cotton soil is capable of causing serious damage to civil engineering projects.

Therefore, it is of the greatest importance to combine these soils with a stabilizing agent before their application [6]. Therefore, it requires an additional technique to ensure its stability before we can begin project work on it. Several methods, such as Surface Compaction, Vibration and Drainage, Injection & Grouting, are performed over the soil as is, or on soil mixed with cement, lime, fly ash, Geomembrane & Geotextiles, to enhance the soil's properties. These techniques will result in Precompression and consolidation, Stabilization and Soil Strengthening. The majority of researchers are focusing on stabilization methods because they increase soil strength and reduce construction costs by utilizing locally available materials. There are primarily three forms of stabilization: physical, mechanical, and chemical. After either physical or chemical stabilization, mechanical stabilization is necessary [7].

Numerous researchers have examined the engineering characteristics of expansive soils [8, 9]. The research of the geotechnical characteristics of a Thai expansive soil stabilized with recycled calcium carbide residue (CCR) revealed that clay treated with 5 to 7 percent of recycled CCR is suitable for use as pavement and fill sub-base material. "DISC HARROW" can be used to mix fly ash and expansive soil in the appropriate percentage, as suggested by the investigation of the effects of varying proportions of fly ash on the physical expansive soil properties analyzed the clayey soil stabilization from Kerala (India) following the addition of fly ash (FA)and CCR. It has been measured that the adding of 10% CCR increases the treated soil's strength to its optimum level.

Chemical stabilization is one of the cost-effective ways to enhance the durability and strength of expansive soils used in construction. With this in mind, researchers have utilized cement and lime to stabilize expansive soils in order to increase its strength and decrease its swelling-shrinking characteristics [10]. Though, numerous researchers have noted that the production of cement and lime is harmful to the environment and energy-intensive. [11] report that a large amount of refuse generated by a variety of industries, including fertilizer production, power generation, metal processing and extraction, agriculture, and mining, remains unused in lagoons and waste disposal sites. Consequently, numerous researchers have investigated the possibility of substituting predictable stabilizing materials such as cement and lime with industrial residue.

According to [7], adding 2% cement and 20% sand to expansive black cotton soil decreases the expansion index, plastic limit, and liquid limit from 6% to 46% by 30% and 10%, respectively. The optimal moisture content is reduced by 38%, while the maximum dry density (MDD) increases by 12%. In a study conducted in Las Vegas, Nevada, United States, the impact of adding 10–75% silica sand to expansive soils was evaluated [12]. The results showed that the addition of sand reduced the soil's expansion and plasticity, reclassifying these soils as low-expansive.

The addition of cement, sand, and fly ash to black cotton soil in various proportions resulted in an increase in (MDD) from 2.02 to 2.07 and an increase in the CBR percentage values of the mixture from 2.01 to 5.52 [13, 14] investigated the capability of an industrial byproduct, CCR, to enhance the permanent deformation behavior of BCS. The incorporation of CCR reduces the BCS's plasticity and increases its shear strength. Due to their abnormally high-volume change feature, the studies indicate that expansive soils have a high level of plasticity and shrink-swell behavior. An example of expansive soil is black cotton soil. These soils can increase to 10% of their original volume with the introduction of water and compress into a popcorn-like shape. The unusually high swell and shrink features of these soils cause severe differential settlement damage to civil engineering constructions [15].

Therefore, it is necessary to adjust the feeble expansive soils properties to increase their strength. Lime, along with other additives, has been extensively used to stabilize fragile soils. The unconfined compressive strength (UCS) and the plasticity index (PI) of black cotton soil (BCS) mixed with lime particles and cement were found to change significantly in a previous study [16]. The swelling and shrinkage behavior of BCS has been attributed to the presence of the mineral montmorillonite. This type of expansive soil is also referred to as black cotton soil because it is suitable for cotton cultivation, which is how it got its name.

BCS covers approximately one-fifth of the total geographical area in India. This soil is found in Andhra Pradesh, Madhya Pradesh, Karnataka, and Gujarat, which are Central, Southern, and Western Indian states. Literature [17] discovered that the engineering characteristics, such as swelling behavior, of problematic BCS can be measured by introducing admixtures such as cement dust, lime, MSWI ash, wood powder, and ground granulated blast furnace slag (GGBFS) [18] demonstrated that black cotton soil is unsafe because of its anomalous change in volume with varying water content. According to [19], when BCS is stabilized with cement kiln dust (CKD) and quarry dust, its plasticity index and liquid limit decrease. This problematic soil has caused significant damage to American civil engineering structures. The only region where these soils are is the arctic [20]. The expansive soils have unfavorable engineering properties, such as low bearing capacity values and moisture variation.

Roughly 95% of the world's highways are constructed with flexible pavements. Sub-grade is the natural soil upon which additional strata are built [21]. Frequently, it is exposed that the existing subgrade is expansive or weak, i.e., a small moisture condition change in results in a important volume change within a brief period. In such instances, subgrade is modified with the aid of specific additives. This modified subbase is known as subbase. Above the subbase is the base course, which is a load-bearing stratum composed primarily of different-sized, high-quality aggregates. The surface course, which consists of fines, aggregates, infill, and binder, is layered on top. This layer is in straight contact with the traffic burden; therefore, a material of superior quality is an absolute necessity [22].

A substantial portion of flexible pavement is comprised of aggregates obtained from particular quarry locations. Their extraction method consists of drilling, blasting, pulverizing, and excavating. These methods are highly unmaintainable, as a huge amount of refuse is produced during the process is either refilled at quarry sites or discarded abruptly, posing numerous threats to the ecological cycle [23]. Likewise, bitumen, which is used as a binder in the surface course, hurts human health and the environment. At temperatures between 165 and 200 degrees Celsius, it is mixed with aggregates, emitting fumes and vapors into the atmosphere. These fumes comprise aerosol and greenhouse gas components that induce carcinogenicity and irritation of the respiratory and skin tract during occupational exposure [24].

Despite all of these negative effects, the construction cannot be restricted because they are essential to the nation's growth. Therefore, it is essential to seek out resources that can contribute to sustainability by decreasing natural resources consumption, alleviating landfill pressure, and preserving structural integrity. Utilizing locally generated refuse is an important step in the right direction [25].

Expansive soil covers large parts of Africa, Australia, India, South America and the United States. These expansive soils tend to show a large magnitude of volume change behaviour with the change in moisture content, resulting in various degrees of foundation and structural distress [26]. Damage is observed to be severe under low foundation pressures. Several additives like cement, cement kiln dust, fly ash, lime, lime-fly ash mixtures and quarry dust, etc. can be used to improve the geotechnical properties of the expansive soil, particularly to control its volume change behaviour. Fly ash and quarry dust are materials generated as a by-product on burning coal in thermal power stations and the crushing/quarrying of rocks to produce aggregates, respectively. These materials are disposed of in huge quantities in the landfills annually. The choice of fly ash and quarry dust to stabilize expansive soil will not only improve the geotechnical properties of the amended expansive soil but also help in waste utilization and management particularly when used in large volumes making these materials ideal additives for improving the quality of the subgrade for road construction [27, 28].

Fly ash is lighter than soil and is larger than clay fraction. It increases the particle size of soil through flocculation and aggregation. The cementitious products formed when fly ash reacts with water in the soil matrix also limit the plastic nature and swelling tendency of the expansive soil [29] studied the effect of lime, cement and fly ash as stabilizers on properties of expansive soil like its gradation, consistency limits and swell behaviour. The study also documented the effect of curing for 7-days and 28-days. The gradation of the soil changes from high compressible clay and low compressible clay with the addition of the additives cement, lime and fly ash. The plastic nature and swell potential of the expansive soil decreased with the addition of all three additives. The swell potential on adding 20% fly ash produced a similar decrease as that of adding 8% lime. Swell potential of the fly ash-treated soil was also observed to decrease with ageing.A study investigated the effect of fly ash obtained from the Soma power station in Turkey on expansive soils from two sites in northern Cyprus [30]. The fly ash used was of Class C type with self-cementing properties. The results indicated that the addition of fly ash modified the texture and plastic behavior of the expansive soil. Furthermore, volume change was limited due to the cementation process initiated by the fly ash. This cementation between soil particles also reduced the clay-sized fraction in the soil, thereby limiting the cation exchange capacity of the treated expansive soil. The findings demonstrated that fly ash makes the soil more granular, reducing its surface activity and water absorption capacity. The study reported a 50% reduction in free swell index, swell pressure, and swelling potential with the addition of 20% fly ash, along with decreases in the liquid limit and plasticity index. In a separate study, fly ash from the Jinling thermal power station was used to improve the properties of expansive soil in Hefei City, China [31]. Their study compared the efficacy fly ash and fly ash – lime mixture in controlling the plastic behaviour and swelling tendency of the expansive soil. Gradation of the soil changed with addition of stabilizers as reported from other studies like [30, 32, 33] with decrease in clay sized fractions and increase in silt and sand sized fractions owing to flocculation. This change in gradation will decrease the specific surface area of the soil particles reduce their affinity to water. Swell parameters like free swell, linear shrinkage, swell pressure and potential also decreased on addition of fly ash and fly ash - lime mixes. Ageing also reduced the swelling nature of the expansive soil after treatment with fly ash and fly ash – lime mixes because of the formation of CAH and CSH [34]. used fly ash in combination with bio-cement (FABC) to improve the expansive soil. Their study showed that 25% of fly ash and bio-cement optimally decreased the swell potential, liquid limit, plastic limit and plasticity index of the expansive soil. The reduction in swelling behaviour and plastic nature of the soil was attributed to flocculation and aggregation of soil particles promoted by bio-cement [35]. also used fly ash and lime to improve the properties of expansive soil as [36] On adding 5% lime with fly ash, the free swell index decreased by 10% and plasticity index by 64.9%.

Expansive soil stabilized with fly ash show better strength owing to the pozzolanic nature of fly ash. Fly ash reacts chemically in the presence of water and forms cementitious products like CSH and CAH that contribute to enhanced strength, particularly long-term strength of the stabilized soil. Also, the fly ash produces divalent and trivalent cations under ionized conditions, encouraging flocculation of dispersed soil particles, leading to aggregation, another cause of strength gain. Cationic exchange between the expansive soil and fly ash leads to increased strength [30]. An increase of 27% in the undrained shear strength of soil stabilized with 20% fly ash at a water content of 20% was observed by [33]. Their study also highlighted that the undrained shear strength of stabilized soil decreased sharply with increasing water content, regardless of the fly ash content. In a related investigation, [37] noted that while fly ash alone did not result in significant strength gains, the addition of 1–3% lime as a secondary additive markedly enhanced the strength of the stabilized soil. These strength improvements were also found to increase substantially over time. The study by [38] similarly reported that the use of secondary additives in conjunction with fly ash can significantly enhance soil strength. For instance, [30] incorporated bio-cement as a secondary additive with fly ash and documented an increase in strength from 142.6kPa to 719.4kPa when 25% of the fly ash–bio-cement (FABC) mixture was added to expansive soil. Additional observations by [36] showed increased unconfined compressive strength at both 10% and 20% fly ash content. Furthermore, incorporating 5% lime as a secondary additive notably improved strength, attributed to an increased rate of hydration. Early strength development due to lime addition was also emphasized in the findings of [35], who observed that lime, when used alongside fly ash, accelerated the initial strength gain of expansive soil. Differences in stress–strain behavior between fly ash-stabilized soil and fly ash–lime mix-stabilized soil were noted, with the former showing a gradual post-peak stress reduction, while the latter exhibited a sharp drop in stress, indicating a stiffer soil matrix. To evaluate tensile strength, [38] employed the Brazilian split tensile strength method and found an increase of 125.44 kPa with the addition of 20% fly ash, which improved further with the inclusion of lime as a secondary additive. Lastly, [39] reported that the unconfined compressive strength of expansive soil increased by 49.3% upon the addition of 10% fly ash.

Fly ash can be effectively utilized to enhance subgrade strength, thereby making expansive soils more suitable for road construction. This improvement is largely attributed to the pozzolanic nature of fly ash. The use of fly ash for subgrade improvement has been identified as a sustainable practice [40]. In one study, a mixture of rice husk ash and fly ash led to a 12% increase in the California Bearing Ratio (CBR) value [41]. Another investigation reported that a combination of 20% fly ash and 8.5% lime resulted in a 5.7% increase in the CBR value [38].

A particularly notable enhancement in subgrade strength was achieved using enzymatic fly ash and 2% lime, as reported in [42], where the soaked CBR value increased by 800% and the unsoaked CBR value by 1000%. This dramatic improvement was attributed to the formation of calcium silicate hydrate (CSH) and calcium aluminate hydrate (CAH) compounds. Consequently, the pavement thickness was reduced by 60% due to the improved load-bearing capacity of the treated soil. Additionally, an increase of 6% in the CBR value was observed with the incorporation of 10% fly ash [39].

Quarry dust (QD) is a non-plastic, granular by-product of the stone crushing process and is abundantly available, comprising nearly 25% of the output from a typical crusher unit. According to [31], the granite industry alone generates approximately 175 million tonnes of dust annually. This massive volume of waste presents significant health and environmental risks due to its non-biodegradable nature, highlighting the urgent need for effective disposal and utilization strategies.

Large-scale reuse of quarry dust holds considerable potential for geotechnical applications such as backfill material, embankments, and road construction. In a study conducted by [43], QD was found to exhibit higher shear strength than sand, along with excellent drainage and high permeability. These characteristics are attributed to its larger particle size, making it an ideal additive for enhancing the strength of expansive soils. Moreover, QD contains a substantial amount of silica, which reflects its pozzolanic properties—offering yet another advantage for its use as a soil stabilizer.

In their study, [43] reported that the optimum moisture content (OMC) of quarry dust (QD) varies between 9.3% and 12.6%, despite its granular and non-plastic nature. This variation was attributed to the presence of silt-sized particles within the QD. The same study also observed that mixing QD with different types of soil—such as laterite, marine clay, kaolin, and sand—resulted in an increase in maximum dry density (MDD) and a corresponding decrease in OMC.

The stabilization of expansive soil using a combination of QD and lime was examined by [44], who found that the addition of QD alone led to reduced OMC and increased MDD. However, when lime was used as a secondary additive along with QD, the OMC increased and MDD decreased. Similarly, [45] observed that combining QD with lime led to a marginal drop in OMC and a gradual increase in MDD.

In another investigation, [46] used QD in proportions ranging from 10% to 40%, and noted a decrease in OMC from 21.1% to 12.6% along with an increase in MDD from 1.6g/cc to 1.76g/cc. [40] experimented with 10% QD in combination with 4%, 8%, 12%, and 16% cement kiln dust (CKD), reporting that MDD decreased and OMC increased without curing. However, with increased curing time (7, 14, 21, and 28 days), MDD increased and OMC decreased due to pozzolanic reactions.

Further, [41] used varying combinations of lime (3%–18%) and QD (22%–37%), identifying that a mix of 13% lime and 27% QD yielded the highest MDD at the lowest OMC. Supporting these findings, Sudhakar et al. [48] observed that increasing QD content from 10% to 25% resulted in an increase in MDD and a decrease in OMC from 20.5% to 14%. The authors attributed this improvement to the denser packing of soil particles facilitated by the larger particle diameter of QD compared to expansive soil.

Numerous studies have demonstrated that the addition of quarry dust (QD) enhances the strength characteristics of expansive soil. To further improve soil performance, secondary additives such as lime, cement, and cement kiln dust (CKD) have also been incorporated alongside QD. In one investigation, the effect of QD and lime on expansive soil strength was examined by maintaining a constant lime content of 2% while varying QD content from 8% to 38%; the results showed a progressive increase in strength with higher QD content [47].

The stress–strain behavior of QD was found to resemble that of sand, with the secant modulus directly proportional to the applied normal stress, as reported by [43]. In their tests, QD samples exhibited failure strains ranging from 3.2% to 5%, and the cohesion intercept for air-dried QD samples was found to be minimal. Moreover, QD samples displayed slightly higher shear strength compared to sand.

The combined effect of QD and CKD on expansive soil was explored in another study, which found that unconfined compressive strength (UCS) increased and failure strain decreased with increasing curing time and CKD content [19]. Additionally, [45] evaluated a mix of fly ash and QD in a 1:2 ratio, replacing 15% to 75% of the soil's dry weight. The maximum UCS was observed at a 45% replacement level, beyond which strength declined. This reduction was attributed to insufficient cohesion at higher QD proportions. Supporting these findings, Sudhakar et al. [48] reported a 5.9% increase in UCS when 15% QD was added to expansive soil, further reinforcing the potential of QD as an effective stabilizing agent.

The granular nature of quarry dust (QD) makes it an effective additive for stabilizing expansive soils, particularly in road construction applications. Several studies have examined the impact of QD on the California Bearing Ratio (CBR) of expansive soils and reported significant improvements. For example, [45] observed that the combination of lime and QD led to a notable increase in the CBR value. Additionally, the stabilized soil exhibited low sensitivity to moulding water content, indicating its high suitability for road works. Their economic analysis also revealed a cost saving of approximately 11.5% per square meter of pavement area.

Similarly, [46] reported that CBR values increased consistently with the addition of QD, with the maximum improvement observed at 40% QD content—raising the CBR value from 1.75% to 7.05%. In another study, [48] assessed the effect of varying QD content (10% to 25%) on expansive soils using the group index method. Their findings showed a reduction in required pavement thickness with increasing QD content, indicating enhanced subgrade strength and improved suitability for road construction.

| BC | QD | FA | FSI | OMC | MDD | CBR | UCS |

| % | % | % | % | % | g/cm3 | % | MPa |

| 72.0 | 12.0 | 16.0 | 83.9 | 11.5 | 1.9 | 4.2 | 3.9 |

| 72.0 | 13.0 | 15.0 | 86.5 | 11.1 | 1.8 | 5.5 | 4.4 |

| 74.0 | 10.0 | 16.0 | 85.0 | 15.3 | 1.6 | 3.7 | 4.1 |

| 79.0 | 9.0 | 12.0 | 88.4 | 15.3 | 1.7 | 3.8 | 4.8 |

| 55.0 | 25.0 | 20.0 | 64.8 | 10.9 | 2.0 | 5.9 | 5.4 |

| 58.0 | 27.0 | 15.0 | 61.8 | 9.7 | 2.5 | 6.3 | 4.9 |

| 54.0 | 22.0 | 24.0 | 62.8 | 9.6 | 2.0 | 5.3 | 4.4 |

| 51.0 | 25.0 | 24.0 | 67.3 | 9.5 | 2.5 | 5.6 | 5.7 |

| 74.0 | 15.0 | 11.0 | 76.4 | 12.2 | 1.7 | 5.6 | 3.3 |

| 89.0 | 9.0 | 2.0 | 81.5 | 14.5 | 1.6 | 3.4 | 4.3 |

| 65.0 | 26.0 | 9.0 | 58.3 | 9.8 | 1.9 | 5.7 | 5.2 |

| 68.0 | 21.0 | 11.0 | 68.0 | 11.1 | 2.5 | 5.8 | 5.4 |

| 59.0 | 27.0 | 14.0 | 57.9 | 11.2 | 2.4 | 5.3 | 4.8 |

| 64.0 | 16.0 | 20.0 | 75.6 | 11.1 | 1.7 | 5.7 | 3.8 |

| 78.0 | 14.0 | 8.0 | 77.0 | 11.5 | 1.6 | 5.2 | 4.1 |

| 86.0 | 11.0 | 3.0 | 96.5 | 15.3 | 1.7 | 3.9 | 4.3 |

| 60.0 | 25.0 | 15.0 | 64.2 | 8.8 | 2.4 | 5.9 | 4.6 |

| 66.0 | 28.0 | 6.0 | 74.2 | 10.9 | 1.9 | 6.0 | 4.3 |

| 83.0 | 10.0 | 7.0 | 92.8 | 16.9 | 1.6 | 3.0 | 4.9 |

| 53.0 | 23.0 | 24.0 | 62.3 | 10.1 | 2.0 | 5.4 | 4.8 |

| 55.0 | 26.0 | 19.0 | 70.6 | 9.7 | 2.4 | 5.9 | 5.1 |

| 74.0 | 14.0 | 12.0 | 86.7 | 13.7 | 1.8 | 5.6 | 3.6 |

| 79.0 | 16.0 | 5.0 | 86.2 | 13.0 | 2.1 | 5.0 | 4.3 |

| 60.0 | 25.0 | 15.0 | 67.0 | 10.0 | 2.2 | 5.5 | 5.0 |

| 62.0 | 25.0 | 13.0 | 59.3 | 11.5 | 2.2 | 5.9 | 5.2 |

| 74.0 | 13.0 | 13.0 | 98.2 | 12.6 | 2.1 | 4.3 | 3.4 |

| 85.0 | 10.0 | 5.0 | 92.0 | 16.0 | 1.8 | 3.4 | 4.5 |

| 87.0 | 8.0 | 5.0 | 89.4 | 14.0 | 1.5 | 4.0 | 4.3 |

| 67.0 | 15.0 | 18.0 | 94.5 | 13.5 | 1.9 | 4.3 | 3.3 |

| 75.0 | 9.0 | 16.0 | 89.7 | 17.9 | 1.6 | 3.4 | 4.8 |

| 52.0 | 26.0 | 22.0 | 60.2 | 9.5 | 2.5 | 5.9 | 4.7 |

| 64.0 | 14.0 | 22.0 | 90.1 | 11.6 | 2.0 | 4.4 | 3.7 |

| 75.0 | 15.0 | 10.0 | 87.0 | 12.0 | 1.8 | 5.0 | 3.8 |

| 85.0 | 8.0 | 7.0 | 89.5 | 13.9 | 2.0 | 3.8 | 4.3 |

| 88.0 | 11.0 | 1.0 | 81.8 | 17.1 | 1.6 | 3.2 | 4.4 |

| 63.0 | 15.0 | 22.0 | 89.1 | 12.7 | 2.0 | 5.4 | 3.8 |

| 88.0 | 10.0 | 2.0 | 81.5 | 14.8 | 1.7 | 3.2 | 4.2 |

| 100.0 | 0.0 | 0.0 | 110.0 | 19.2 | 1.4 | 1.8 | 1.2 |

| 76.0 | 15.0 | 9.0 | 98.1 | 12.0 | 2.0 | 5.1 | 3.7 |

| 81.0 | 10.0 | 9.0 | 89.7 | 14.5 | 2.0 | 3.7 | 5.1 |

| BC | QD | FA | FSI | OMC | MDD | CBR | UCS | ||

|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | g/cm3 | % | MPa | ||

| Training set | Min. | 51.00 | 8.00 | 2.00 | 57.86 | 8.80 | 1.54 | 2.98 | 3.32 |

| Max. | 89.00 | 28.00 | 24.00 | 98.15 | 17.85 | 2.48 | 6.26 | 5.73 | |

| Avg. | 69.27 | 17.63 | 13.10 | 77.29 | 12.28 | 1.95 | 4.95 | 4.50 | |

| SD | 10.93 | 6.85 | 6.10 | 12.60 | 2.41 | 0.30 | 0.96 | 0.62 | |

| VAR | 0.16 | 0.39 | 0.47 | 0.16 | 0.20 | 0.15 | 0.19 | 0.14 | |

| Validation set | Min. | 52.00 | 0.00 | 0.00 | 60.20 | 9.45 | 1.35 | 1.83 | 1.23 |

| Max. | 100.00 | 16.00 | 22.00 | 110.00 | 19.20 | 2.46 | 5.89 | 5.05 | |

| Avg. | 77.20 | 12.40 | 10.40 | 87.69 | 13.71 | 1.90 | 4.16 | 3.89 | |

| SD | 13.59 | 6.28 | 8.28 | 12.04 | 2.71 | 0.28 | 1.17 | 0.99 | |

| VAR | 0.18 | 0.51 | 0.80 | 0.14 | 0.20 | 0.15 | 0.28 | 0.25 |

| BC | QD | FA | FSI | OMC | MDD | CBR | UCS | |

|---|---|---|---|---|---|---|---|---|

| BC | 1.00 | |||||||

| QD | -0.88 | 1.00 | ||||||

| FA | -0.87 | 0.53 | 1.00 | |||||

| FSI | 0.76 | -0.87 | -0.45 | 1.00 | ||||

| OMC | 0.84 | -0.85 | -0.62 | 0.75 | 1.00 | |||

| MDD | -0.75 | 0.79 | 0.52 | -0.63 | -0.75 | 1.00 | ||

| CBR | -0.83 | 0.87 | 0.57 | -0.73 | -0.90 | 0.69 | 1.00 | |

| UCS | -0.49 | 0.58 | 0.27 | -0.65 | -0.41 | 0.53 | 0.42 | 1.00 |

Fly ash when used for stabilizing soil has the potential to interact with ground water or water courses in the neighborhood and is susceptible to leaching due to its amorphous nature making it subject to local environmental requirements.

Machine learning technique is been used in many studies for the accurate prediction [49, 50, 51]. Forty (40) records were collected for experimentally-tested samples of Black Cotton (BC) clay stabilized with Quarry Dust (QD) from 0 to 25 wt % of soil and Fly Ash (FA) from 0 to 25% wt % of soil by replacement. Each record contains the following data:

BC Black Cotton content %

QD Quarry Dust content %

FA Fly Ash content%

FSI Free Swell Index%

OMC Optimum Moisture Content %

MDD Maximum Dry Density (g/cm3)

CBR California Bearing Ratio %

UCS Unconfined compressive strength (MPa)

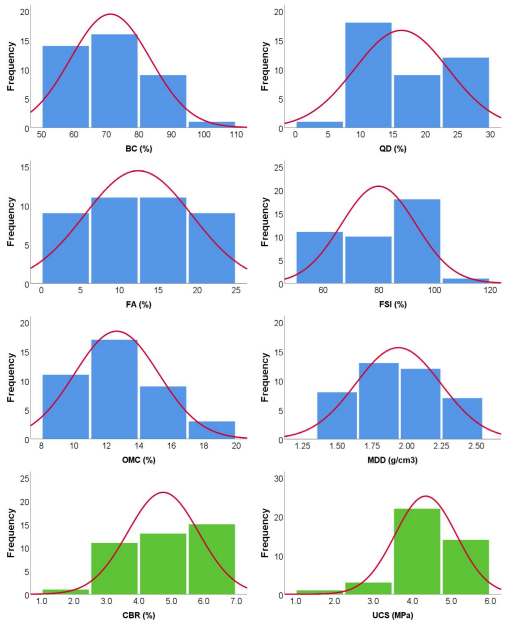

The collected records were divided into training set (30 records) and validation set (10 records). The complete dataset is contained in Table 1, while Tables 2 and 3 summarize their statistical characteristics and the Pearson correlation matrix. Finally, Figure 1 shows the histograms for both inputs and outputs, which represents the internal consistency of the variables [52].

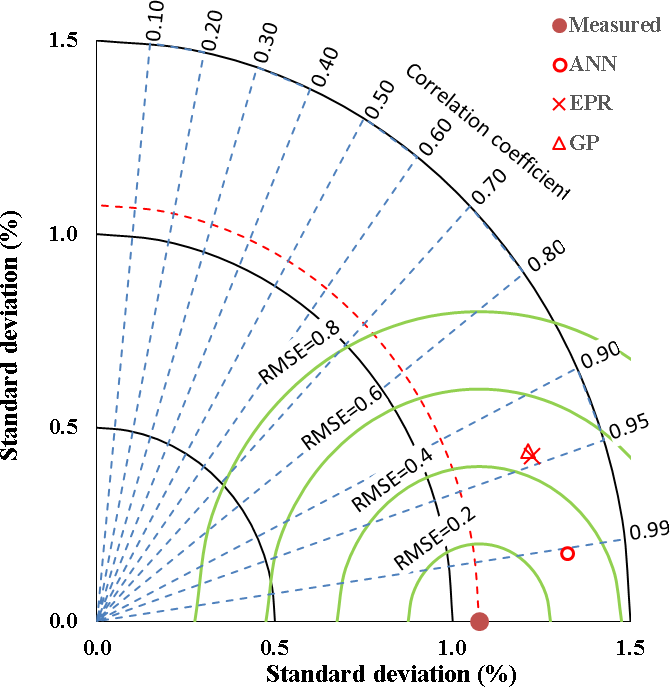

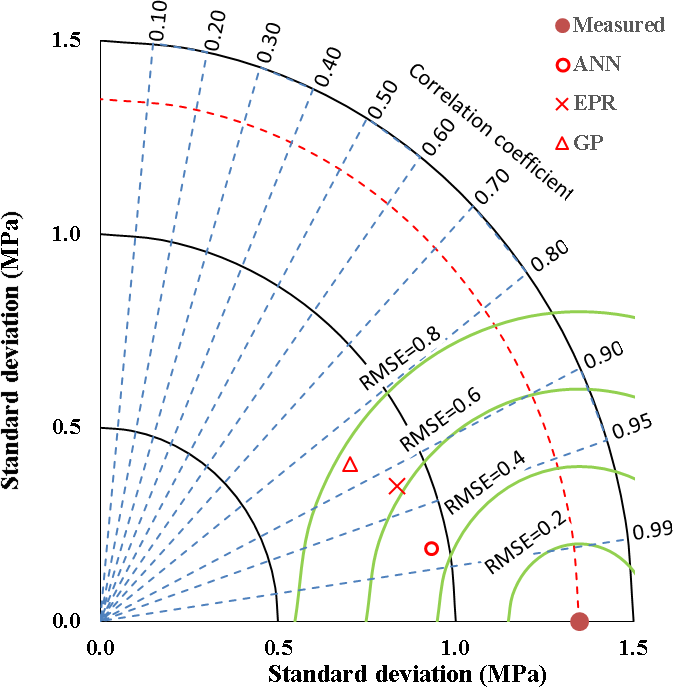

To predict the California Bearing Ratio (CBR) and Unconfined Compressive Strength (UCS) of Black Cotton Clay stabilized with Quarry Dust (QD) and Fly Ash (FA), three distinct Artificial Intelligence (AI) techniques were employed. These techniques included Genetic Programming (GP), three models of Artificial Neural Network (ANN), and Evolutionary Polynomial Regression (EPR), which optimizes polynomial regression using genetic algorithms. The models utilized a collected database and input variables such as Black Cotton Clay (BC), QD, FA, FSI, OMC, and MDD to make predictions.

Each model employed a different approach: GP utilized an evolutionary approach, ANN mimicked biological neurons, and EPR utilized an optimized mathematical regression technique. The accuracy of each model's predictions was evaluated by comparing the Sum of Squared Errors (SSE), mean absolute error (MAE), mean squared error (MSE), root mean squared error (RMSE) and the coefficient of determination (R2) between the predicted and calculated shear strength parameters. In the subsequent section, the results of each model are discussed, and their accuracies are assessed based on SSE, MAE, MSE, RMSE and R2 as follows;

where = coefficient of determination, = sum of squares of results, = total sum of squares, = predicted value of term, = measured value of term, = number of data points, = number of parameter estimation

The GP model that was created exhibits four levels of complexity, with the population size, survivor size, and number of generations set at 100,000, 30,000, and 100, respectively. Equations (6) and (7) represent the output formulas for CBR and UCS, respectively.

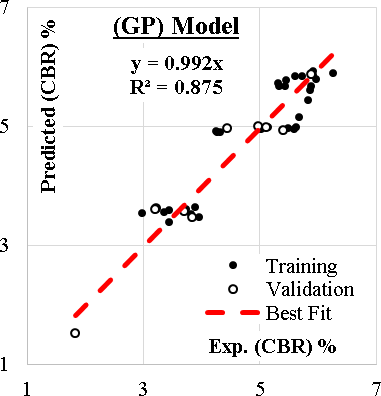

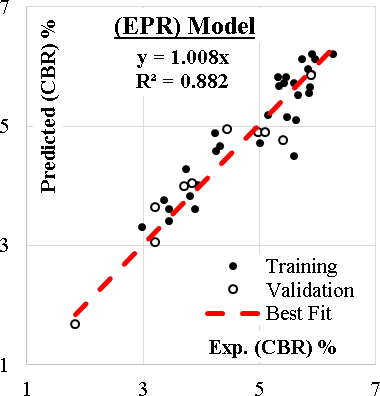

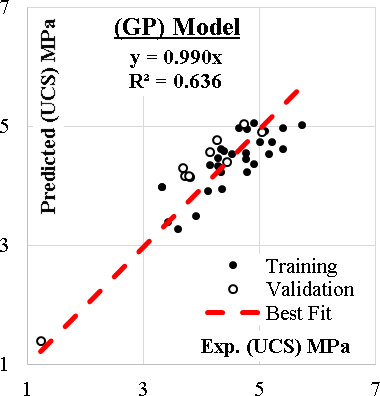

The average error percentages for the entire dataset were found to be 8% and 9% for CBR and UCS, respectively. Furthermore, the R-squared (R2) values achieved were 0.875 for CBR and 0.636 for UCS, in that order.

| H(1:1) | H(1:2) | H(1:3) | H(1:4) | H(1:5) | H(1:6) | (Bias) | |

| (Bias) | 3.60 | -6.02 | -9.57 | -11.62 | -0.45 | -3.44 | |

| BC | -0.76 | -0.06 | -1.17 | 2.47 | 1.42 | -7.56 | |

| QD | -0.50 | -15.16 | 4.28 | -4.74 | -0.84 | 2.60 | |

| FA | 2.93 | 15.40 | -2.32 | 0.31 | -1.21 | 9.97 | |

| FSI | 7.46 | -2.41 | -3.22 | 5.28 | 0.54 | -11.45 | |

| OMC | -6.28 | 5.78 | -0.68 | -3.71 | 0.11 | 3.44 | |

| MDD | 2.71 | 2.05 | 13.32 | 0.41 | 0.87 | -23.21 | |

| CBR | 0.41 | -0.31 | 0.24 | -0.60 | -0.12 | 0.29 | -0.21 |

| UCS | 0.01 | 0.25 | 0.67 | -5.13 | 0.49 | 0.13 | -4.17 |

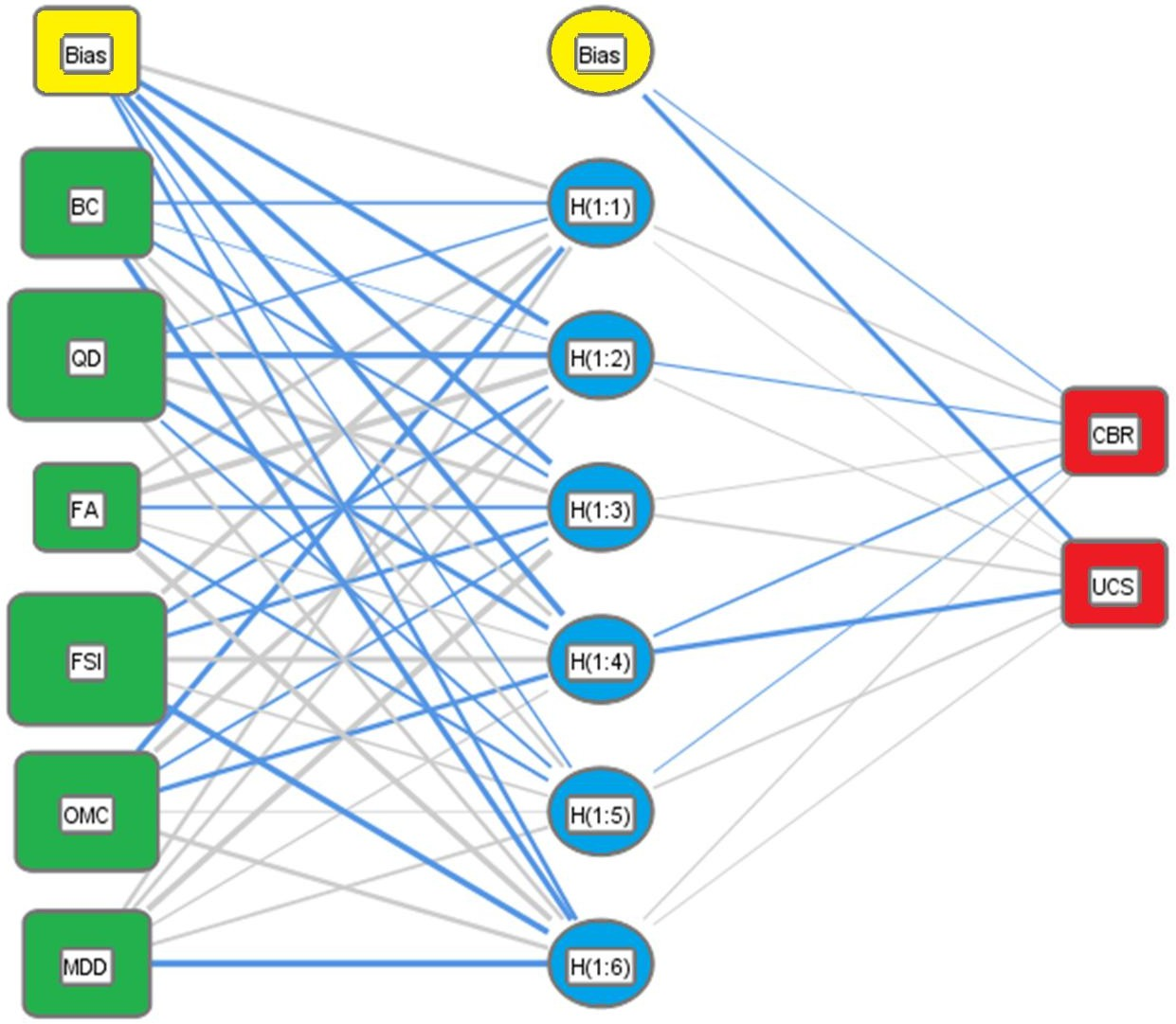

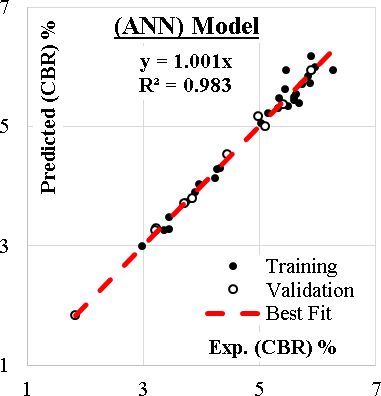

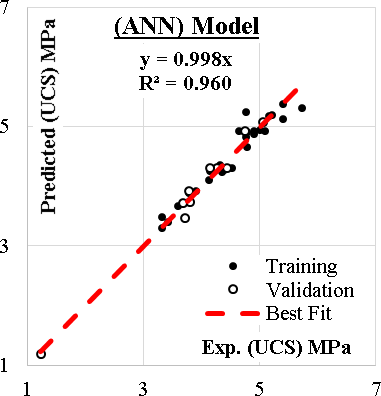

A single artificial neural network (ANN) model was developed to predict both California Bearing Ratio (CBR) and Unconfined Compressive Strength (UCS) values. The model utilized a normalization technique to scale the input values between -1.0 and 1.0, employed the hyperbolic tangent (Hyper Tan) as the activation function, and utilized the back propagation (BP) training algorithm [53, 54]. The network layout is depicted in Figure 2, and the weight matrix of the model is presented in Table 4. The average errors for the entire dataset were 3% and 4%, while the corresponding R-squared (R2) values were 0.986 and 0.960 for CBR and UCS, respectively. Figure 3 displays the relative importance values for each input parameter, indicating that all factors carry nearly equal significance for both CBR and UCS, except Fly Ash (FA), which exhibits a lesser influence.

The observed superiority of the Artificial Neural Network (ANN) model over Genetic Programming (GP) and Evolutionary Polynomial Regression (EPR) can be attributed to its intrinsic capability to model complex and nonlinear interactions among input variables. Unlike GP and EPR, which are constrained by the mathematical structure of explicit equations or polynomials, the ANN learns adaptive mappings through its hidden layers, enabling it to flexibly model interactions such as the combined influence of MDD and QD on CBR and UCS, which may be highly nonlinear and dataset-specific. This flexibility is particularly advantageous when dealing with experimental geotechnical datasets that are often noisy and sparse. The backpropagation algorithm in ANN optimizes parameters locally, allowing it to adapt to subtle patterns and reduce overfitting risksunlike GP's evolutionary search, which may converge prematurely or miss fine-grained correlations. Furthermore, studies such as [1] have shown that ANN outperforms other machine learning models in scenarios where parameter interaction is nontrivial and the dataset does not conform to known analytical forms. In terms of computational efficiency, ANN required approximately 2.5 times more training time than GP and 9 times more than EPR, primarily due to its iterative gradient-based training and multiple weight adjustments per epoch. Specifically, the ANN model was trained for approximately 45 minutes using an NVIDIA T4 GPU, whereas GP and EPR completed training in 18 and 5 minutes, respectively. This computational cost is justified when predictive accuracy is prioritized, especially for final pavement design or field application stages. However, for rapid preliminary estimations or in low-resource contexts, GP and EPR remain valuable alternatives.

The predictive performance and experimental findings of this study align well with prior research on black cotton soil (BCS) stabilization. The ANN model achieved high predictive accuracy (R² = 0.983 for CBR, 0.960 for UCS), consistent with literature reporting improvements in strength parameters using quarry dust (QD) and fly ash (FA). The maximum CBR (6.26%) and UCS (5.73 MPa) values, the QD-FA blends in this study offer comparable performance with lower environmental and economic costs. These outcomes support the use of industrial by-products as sustainable alternatives in pavement subgrade stabilization.

This study demonstrates the practical potential of using quarry dust and fly ash for stabilizing expansive soils in road subgrades, offering a cost-effective and sustainable alternative to conventional materials. The proposed ANN model can support engineers in optimizing mix designs and predicting field performance with high accuracy. Future research should focus on validating the model through field trials, assessing long-term durability under environmental loading, and exploring additional waste materials. Further development of hybrid AI models could also enhance predictive reliability for real-world applications.

| Item | Technique | Model | SSE | MAE | MSE | RMSE | Avg. Error % | R2 |

|---|---|---|---|---|---|---|---|---|

| GP | Eq. 1 | 5.4 | 0.310 | 0.135 | 0.367 | 8% | 0.875 | |

| CBR | ANN | Figure 3, Table 3 | 0.8 | 0.100 | 0.020 | 0.141 | 3% | 0.983 |

| EPR | Eq. 3 | 5.2 | 0.290 | 0.130 | 0.360 | 8% | 0.882 | |

| GP | Eq. 2 | 6.1 | 0.330 | 0.153 | 0.391 | 9% | 0.636 | |

| UCS | ANN | Figure 3, Table 4 | 0.9 | 0.110 | 0.023 | 0.151 | 4% | 0.960 |

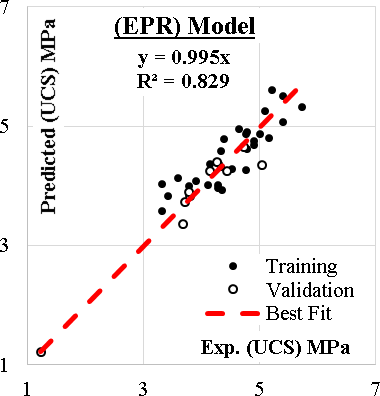

| EPR | Eq. 4 | 3.6 | 0.240 | 0.090 | 0.300 | 7% | 0.829 |

Finally, the developed EPR model was limited to 6thlevel polynomial, for 6 inputs, there are 924 possible terms (462+210+84+28+7+1=924) as follows:

To identify the most influential factors in predicting the values of California Bearing Ratio (CBR) and Unconfined Compressive Strength (UCS), a Genetic Algorithm (GA) [54, 55] technique was applied to a set of 924 terms. The GA process resulted in the selection of 7 terms for CBR prediction and 10 terms for UCS prediction. The outcomes are presented in Equations (8) and (9). The average error percentages and R-squared (R2) values obtained for CBR and UCS were 8% and 7% respectively, with corresponding R2 values of 0.882 and 0.829.

Generally, the relationship between the calculated and predicted values is illustrated in Figures 4 and 5 while the accuracies of the developed models using Taylor charts, a) For CBR, b) For UCS are compared in Figure 6. The summary of the performance accuracies and indices is presented in Table 5.

This research presents three models using (AI) techniques (GP, ANN and EPR) to predict the "California Bearing Ratio" (CBR) and the "Unconfined Compressive Strength" (UCS)for black cotton clay stabilized with Quarry Dust (QD) and Fly Ash (FA)using material contents (BC, QD, FA), free swell index (FSI) and compaction test results (OMC, MDD). The results of comparing the accuracies of the developed models could be concluded in the following points:

(GP) and (EPR) showed almost the same level of accuracy ( 92%) for Both (CBR & UCS). While the (ANN) model presented a higher level of accuracy (96%).

The results indicated that all factors have almost the same importance for both (CBR & UCS) except the Fly Ash content (FA) which has less influence.

The Fly Ash content (FA) did not appear in (GP) or (EPR) models and had the lowest impact in the (ANN) model, that is because it is not an independent variable (FA = 100-BC-QD).

Like any other regression technique, the generated formulas are valid within the considered range of parameter values, beyond this range; the prediction accuracy should be verified.

While the developed AI models (GP, ANN, and EPR) demonstrated high accuracy in predicting CBR and UCS values, a minor limitation lies in the dependency between input variables specifically, the Fly Ash content (FA), which is derived from the total mix proportions (FA = 100 - BC - QD). As a result, FA showed reduced influence in the models. Additionally, like most data-driven approaches, the generated models are best suited within the range of input values used during training. Future studies may focus on validating the models with broader datasets and exploring the inclusion of additional parameters to further enhance prediction performance.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/iece/